As I sit here typing on my laptop, I realize how challenging it can be to put thoughts into words. It's easy to assume everyone has the same experience, but new technicians are constantly entering the industry, and even seasoned techs are now exploring diagnostics. We kind of have a saying around here: "You learn something new every day." In some ways it is kind of hard to believe, but it is true; even when you have been in this game as long as some of us have, if you look to get better or try to help others get better and keep an open mind to the changes in our industry, you really can learn something new every day.

At Certified Transmission we started doing reprogramming in 2005; man, it's hard to believe it has almost been 20 years since then, and we have seen a lot of changes with the hardware and software over the years. I think we used Windows XP back then! However, there are other things that have not changed at all, such as programming errors! I believe that I have done a pretty decent job training our technicians over the years and showing them the correct way to do things, and for the most part, it shows.

We have 15 retail installation facilities that install our reman units every day, and our shops rarely have any type of programming issues. I replace our laptops every four years, and we replace USB and data link cables regularly. I also try to educate our guys on what to look for, what to be aware of, and how to minimize errors when performing the programming. Our outside sales warranty division deals with these issues regularly with shops that we sell to, and some of them aren't as well–equipped or trained as we are. I want to cover a few basic "guidelines" that I believe should be followed, having learned from our own, and our customers' experiences.

Guidelines for ECU Programming

- Ensure Proper Connection:

- Always connect to the OE OBD2 Diagnostic connector.

- Check for aftermarket devices (e.g., remote starters, GPS locators) spliced into the CAN circuit or branching off from the OE connector.

- Use an Approved Battery Power Supply:

- Avoid using a battery charger or a "jump pack" plugged into a charger.

- Ensure the power supply maintains a stable voltage with minimal AC ripple (less than 100MV).

- Set Correct Voltage Levels:

- For most manufacturers, set the voltage to 13.7 Volts.

- For Nissan, do not exceed 13.5 Volts (recommended: 13.2 Volts).

- For BMW, ensure the power supply provides more than 60 Amps.

- Disable Aftermarket Radios for GM Vehicles:

- For 2003–2005 GM trucks, remove the Radio, Radio AMP, and BTSI fuses, regardless of whether an aftermarket radio is installed.

- Check Battery Terminal Connections:

- Ensure terminals are clean and free of corrosion before programming.

- Laptop Power Management:

- Ensure the laptop battery is fully charged or plugged into an AC power supply.

- Adjust power, sleep, and battery settings to prevent the laptop from sleeping or activating a screen saver during programming.

- Minimize Additional Loads:

- Turn off additional loads such as headlights and HVAC blower.

- Ensure Stable Internet Connection:

- If using WiFi, ensure a strong connection; an ethernet connection is preferred.

- Equipment:

- Regularly update and replace laptops and cables.

- Make sure your J2534 tool has the latest firmware installed.

- Training:

- Educate technicians on common errors and how to avoid them.

- Routine:

- Maintain a checklist for programming procedures.

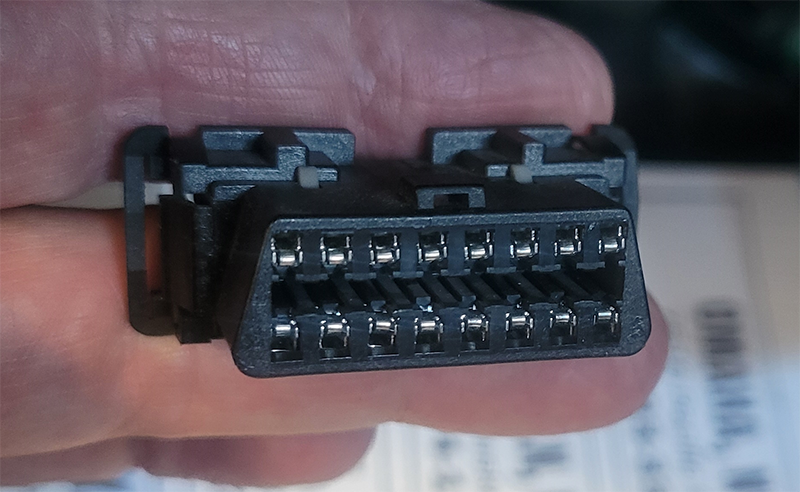

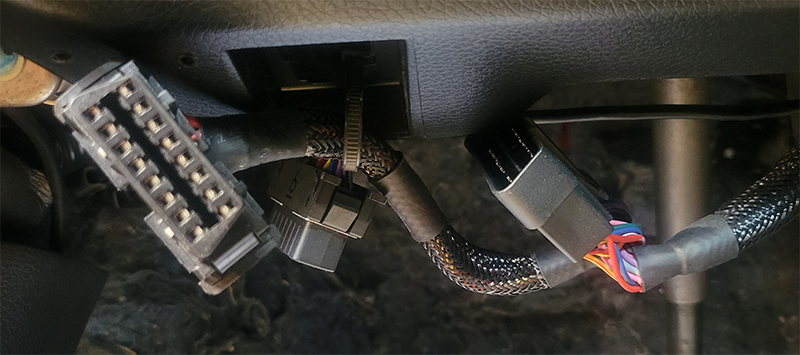

Point #1 is more of an issue now than it has ever been in the past. There are so many used car dealers that are installing GPS tracking devices and some of them are using remote disablers. "Some" of these devices use an OBD2 port replicator and the connector that is installed in place of the factory OBD2 connector is NOT where you need to be plugged into! The easiest way to determine if the plug you are using is the OE plug is to ask yourself this question when you look at it: Is there a terminal in all 16 locations? If there is, chances are this is NOT the OE connector! The exception to this rule is Ford; they added a smart data link module that almost looks like an aftermarket connector, so on 2018/19 and up you are going to have to get under the dash and make sure something is not spliced in there. The first image is an example of an aftermarket OBD2 connector, and the second image is an OBD2 port replicator. (Figure 1 / Figure 2)

Figure 1

Figure 2

We have seen more programming issues by far with GM, but Ford and Stellantis have their own share of different problems, but they are not usually associated with failed programming events. Ford seems to have misplaced some files, the most prevalent is the 6F50/55 solenoid strategy & body ID numbers. The tool will load a strategy based on the solenoid body ID if the strategy number is not found, and while not ideal and does require a bit more of a relearn and drive procedure, it will not stop you from getting the vehicle out of the shop. This is also not something that we, nor any transmission remanufacturing facility, can have any control over. Keep your head in the game, pay attention, and remember that programming an ECU is a sensitive procedure, and care must be taken to follow instructions correctly and minimize the risks that are out there.

Certified Transmission

Certified Transmission