There are a lot of us in this industry that have been that have been at it for a long time, and I think most of us have said more than a few times, "Well that's a new one." I don't know how many others of you out there have come across this problem before, but I know in my personal experience I have not. While this is not a terribly technical story, it is one that we found interesting, and as you will see, it had a scenario along the way that would make it a little more difficult to figure out.

What I am referring to occurred on a 2008 Chevrolet Trailblazer SS. This vehicle originally came into our shop with a concern of a leak between the transmission and transfer case. One thing to note: the transmission had recently been rebuilt by another shop, and the problem had started shortly after the work they had performed. As we all know, getting a good description of the concern and any information about previous work from the customer is very helpful. We are fortunate here that our service writers make this a priority, and it is a real time-saver in many situations.

As is standard procedure, once we have the concern and other pertinent information the vehicle is brought in for a visual inspection. In many cases when the vehicle has a leak concern or a vibration, I like to bring it in the shop and inspect it first before driving it. Sometimes the concern is an operational problem, and the customer either doesn't know or doesn't mention that it does leak. By bringing it in first, if it is leaking and it is not clear where it is coming from, I can clean it up at that point and drive it once rather than driving it first, finding out that it has a leak, then having to clean it up and drive it again to find the source. I can't tell you how many times a vehicle has come in with a leak that was about to blow a cooler line off, or a vibration and the driveshaft was about to fall out.

There was fluid found hanging off the bottom of the transfer case where it mated up to the extension housing, but it was not the source of the leak. The transmission vent hose was routed above the transfer case and it was pretty easy to tell that fluid had come out of this vent onto the transfer case. My first thought was that transmission overheated and vented fluid. I scanned for codes thinking I may see an over temperature code, transmission component slip code, or something like that. No codes were in the system. At this point I had not yet done the most basic thing: check the fluid level and condition.

I checked the fluid and to my surprise it did not show any signs of overheating, but was overfilled. At this point I kind of assumed (we all know the saying) that the installing shop overfilled the transmission. When we do an inspection on the vehicle, we make it a point to check all the fluid levels, including engine oil. On this vehicle, when I checked the level of the transfer case I was surprised to find in was basically empty. We filled the transfer case up, removed the extra fluid in the transmission, cleaned up the fluid and went for a couple different extended road tests throughout the course of the day.

The vehicle sat overnight and in the morning we checked fluid levels again and found the same condition but on a smaller scale. Now most of us have come across the opposite problem, where the transmission is low and the transfer case is overfull, but on this vehicle we have the opposite problem. Could a failing transfer case input seal cause fluid transfer like this? It was time to get authorization to pull the transfer case and do some investigating.

After our technician removed the transfer case we inspected the input seal. It did not appear to be damaged as far as the rubber part looked and the spring was intact. We checked to see if the seal was correct for the application and it was. We inspected the housing that the seal is driven into and it looked acceptable also, so I didn't know what to think. We decided to make sure that the vent on the transfer case, or any of the hoses going to it, were not blocked. They were all clear. Do we just try another input seal and see what happens?

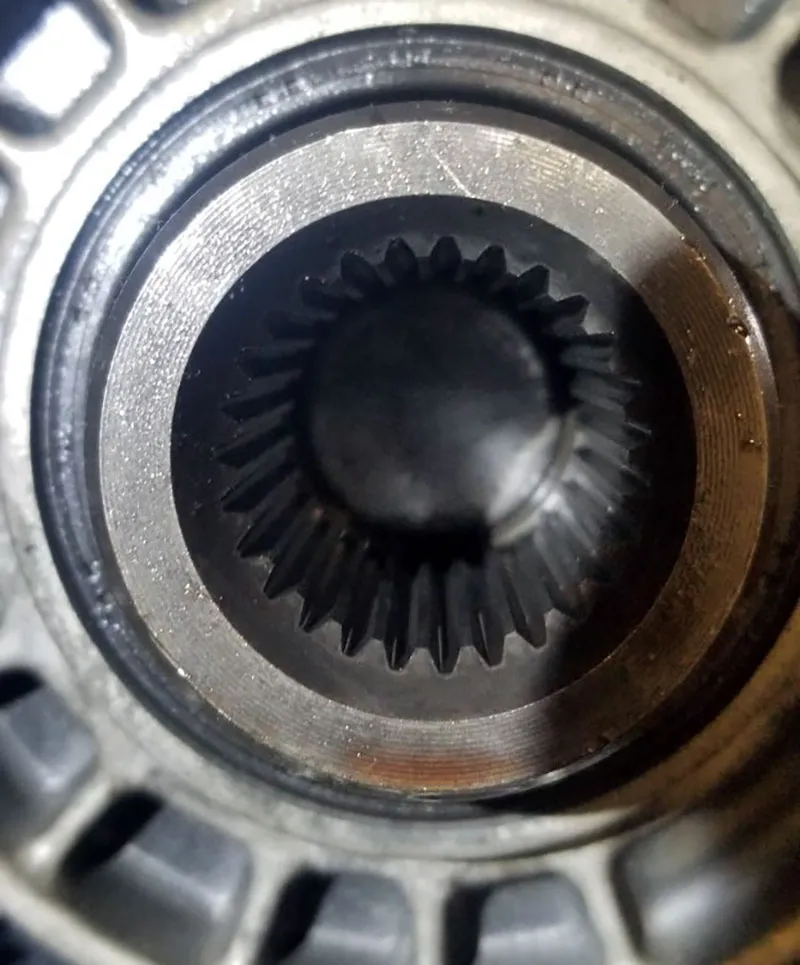

As I mentioned before, this vehicle had been worked on recently, but we were not able to find out if the input seal had been changed at that time. We happened to have another GM transfer case sitting on the bench that had been replaced with a remanufactured one. It was not out of the same vehicle but was the same style. Scratching our heads and looking at the unit that had been previously replaced, we noticed that the "plug" that is at the bottom of the splines in the hole of the input looked like it was not positioned as far down in the splined hole of the input. (FIG 1). I know that one will be hard to see in the picture.

Figure 1

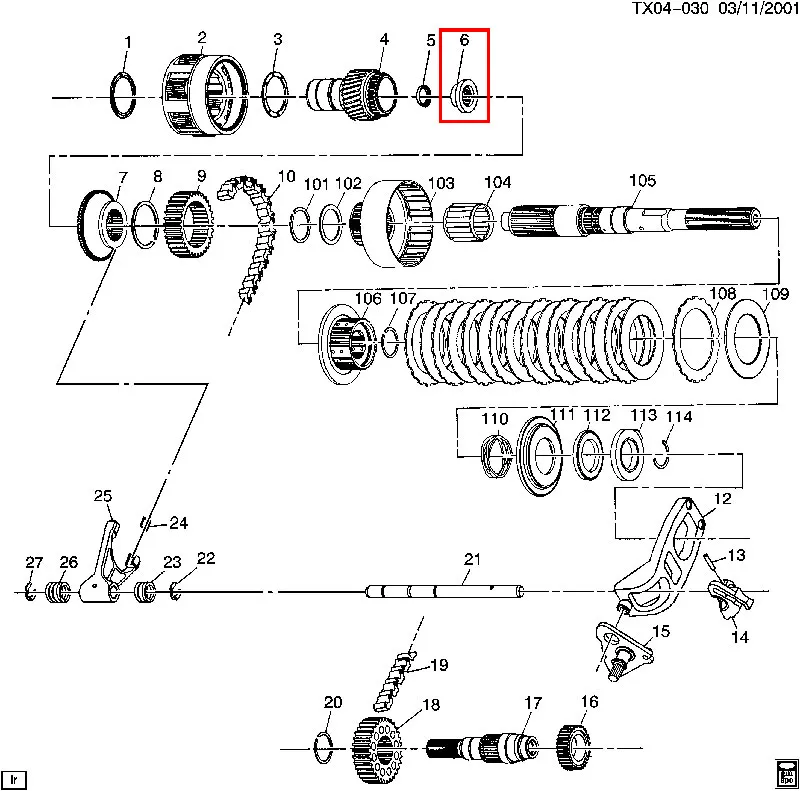

We did a quick measurement and found that the plug in the bottom of the hole was more than a quarter inch deeper in the hole, and further inspection showed a witness mark on it consistent with the size of the machined area of an output shaft, also hard to see in the picture. Next we decided to pull up an exploded view of the transfer case. (FIG 2). The "plug" (#6 in exploded view) we were looking at had bonded rubber on it and also acted as a seal. Here is where the odd scenario that I referenced earlier comes into play. We contacted the customer and had them come down so we could show them what we had found, because we were not sure if there was any other damage to the internals of the transfer case, customer had driven it with no fluid in transfer case for an unknown number of miles, so we recommended installing a remanufactured one. The customer agreed, and we ordered the reman unit. After returning from a test drive on another vehicle the installing technician called me over saying there was a problem. When he went to stab the transfer case onto the transmission it stopped before it would fully mate up to the transmission to transfer case adapter, it was bottoming out on the output shaft. We learned that this transmission when rebuilt by the other shop had been fitted with some performance upgrades including an aftermarket output shaft (FIG 3).

Figure 3

Figure 3

Now it was making sense. Upon measuring the length of the output shaft that was in the vehicle against one in a transmission we had on the bench, the one in the vehicle was longer. The theory we developed was that when the transfer case was installed after the transmission rebuild, the installing tech did not make sure it was installing flush and probably pulled it up with the bolts. This caused distorting of the seal and allowed fluid to actually pass from the transfer case to the transmission.

We talked to the guys that build the transfer cases and asked how the plug was installed, and they let us know that it is driven from the inside out. We asked if it could be driven in a bit so we could gain a little clearance between it and the output shaft. It sounded like we could carefully drive it back down, just enough to clear so the output shaft could not damage it. We double checked our measurements and installed it.

I wanted to put a few miles on this vehicle at this point, and since it was at the end of the week we also let it sit over the weekend. The next week everything looked ok and the vehicle was delivered. After a couple weeks of driving and rechecking it, everything was as it should be and the vehicle has been out on the road for several months now.

We are happy that the installing technician alerted us to the problem and really helped to point us in the right direction. Your installing techs are a very valuable part of your team; I think sometimes we forget that. In this case, paying attention to the basics helped to solve what we felt was a pretty unusual problem.

Certified Transmission

Certified Transmission