At some point, a misdiagnosis is inevitable for any technician, and we sometimes blame an innocent component as the cause of the symptom. The following are examples where the wrong part was replaced in error.

Misleading Noise

A 2002 Lexus RX300 with a 3.0-liter V6 engine and U140F transmission was brought to our shop with the complaint of "A grinding noise when taking off from a stop." The customer stated that this had been intermittently occurring for about a year. They also stated they make frequent stops. They indicated that there were no warning lamps on. A different shop had replaced both front axles, but that did not fix their issue. Another shop replaced the transmission and the PTU hoping that it would fix the noise.

The results of our evaluation revealed no DTCs stored in any of the systems. After several consecutive stops, we were able to duplicate the customer's concern of a grinding sound when stopping. There was also a judder feel on take-off. We suspected the transmission was at fault again. There was no indication of an issue on the scan tool PIDs.

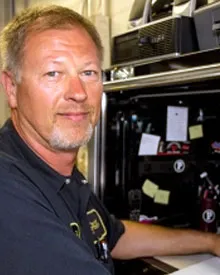

Scratching our heads, we started a random search of potential causes. A TSB containing information about noise and vibration was found, SU007-02. (Figure 1)

Figure 1

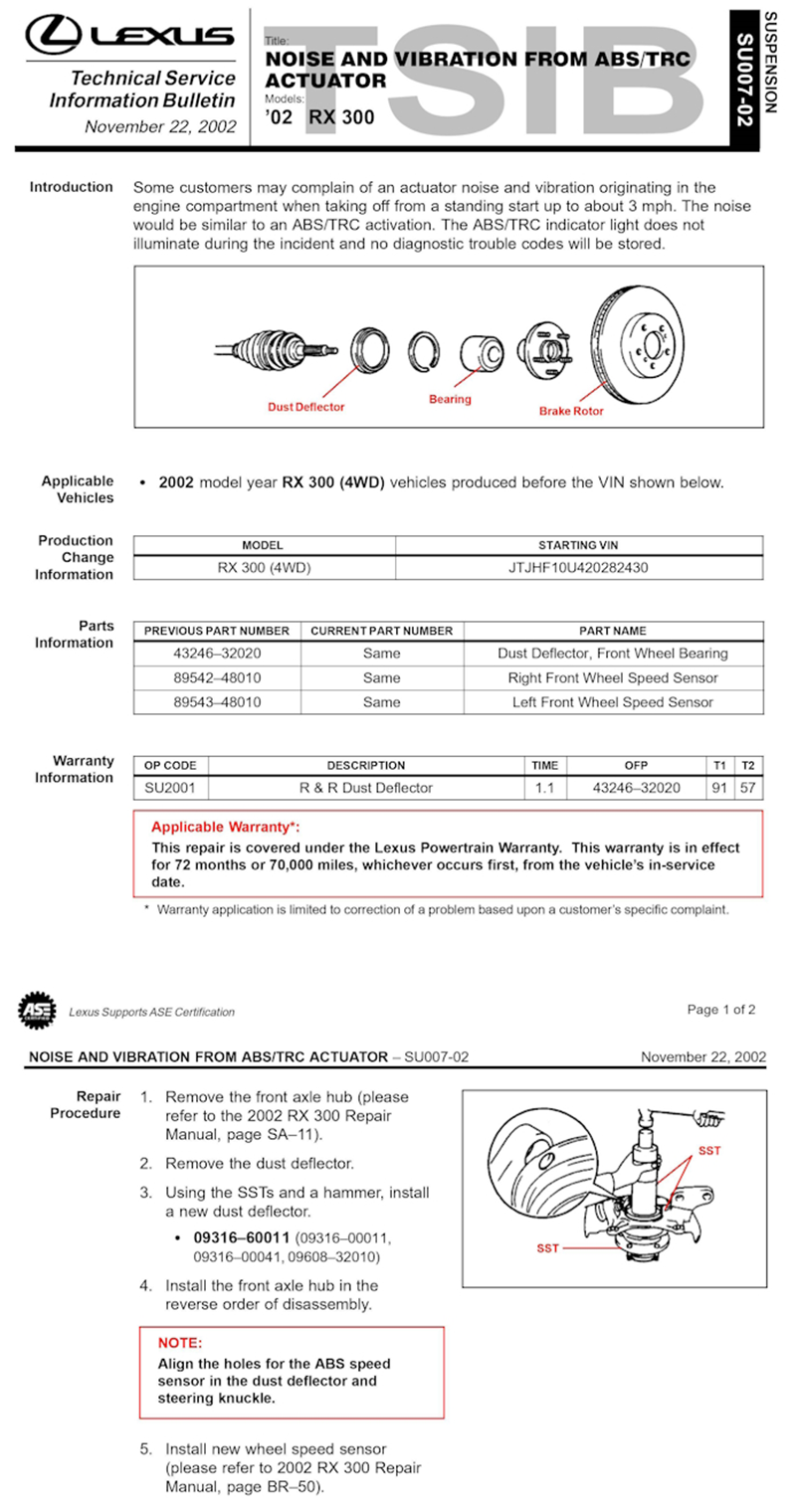

With this information in hand, we drove the vehicle again monitoring the wheel speed sensors. What we noticed was that, at low speed under 3 mph, the right rear wheel speed sensor was dropping out and reading 0 mph. This was activating the traction control and causing noise and vibration feel. (Figure 2)

Figure 2

Upon inspection, we found that the connector was secure and that there were no visible cuts or breaks in the wiring. We removed the speed sensor and did a visual inspection, and we found that the magnet was covered in metal particles. (Figure 3)

Figure 3

Replacement of the sensor solved the customer's concern. The TSB led us to look at the ABS system as a possible cause, but we didn't have to complete everything outlined in the TSB to correct the customer's concern. We returned the vehicle to a very happy customer.

Hard Shifting

A 2008 Buick Lucerne with a 3.8L engine and a 4T65E transmission was brought to us for an intermittent hard shift on acceleration. The preliminary scan for codes showed only two DTCs stored: P0112 (intake air temperature low voltage) and P1112 (intake air temperature intermittent low voltage). This indicated that the sensor was grounding. If there had been an open circuit, it would have a high voltage DTC. The CEL was not on now, which suggested to me the DTCs were history codes, and the issue may not be active at this time.

The vehicle was driven for an extended period without any hard shifting. A long grade was coming up and once the vehicle was accelerated to make the grade, the CEL illuminated, and the transmission began to shift hard. Once over the grade the CEL turned off and the transmission started shifting normally. When the CEL was on, the codes were checked and the two IAT codes were present. At this time, it was apparent that the IAT codes were related to the shift concerns.

Years earlier we had seen a 2008 Oldsmobile that had the same engine and transmission combination. A transmission had just been installed and a final road test was performed. On the final road test, the transmission was shifting hard. This was not typical of the 4T65E, generally. A check of the DTCs in the computer showed an IAT sensor fault code. At that time, we had found that the technician had not plugged in the IAT sensor. After the sensor was plugged in, the DTC cleared, and the transmission worked normally.

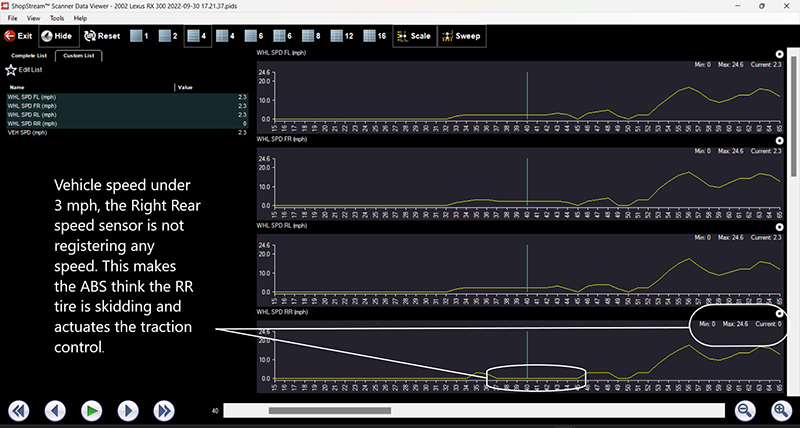

Back to the subject Lucerne, the IAT was inspected on and found to be plugged in. During a quick glance of the wire harness, there was a section that was up against the braided brake hose leading from the master cylinder. The wires would move when the engine was torqued on acceleration and ground. That is why the DTCs had low voltage codes. The wires were repaired, taped and rerouted to avoid any contact. The vehicle is now working correctly, and the customer is happy. (Figure 4)

Figure 4

Inoperative Speedometer and Odometer

A previous customer of ours called us about her 1997 Honda Civic 1.6L 4spd Auto. We had installed our remanufactured transmission several months previous. Her new concern was that her speedometer and odometer did not work, and another shop told her it was a transmission issue, so she called us.

The vehicle was towed to our shop, and we found the battery was completely dead. We jump-started the vehicle, and it started and ran properly so we drove it into our bay.

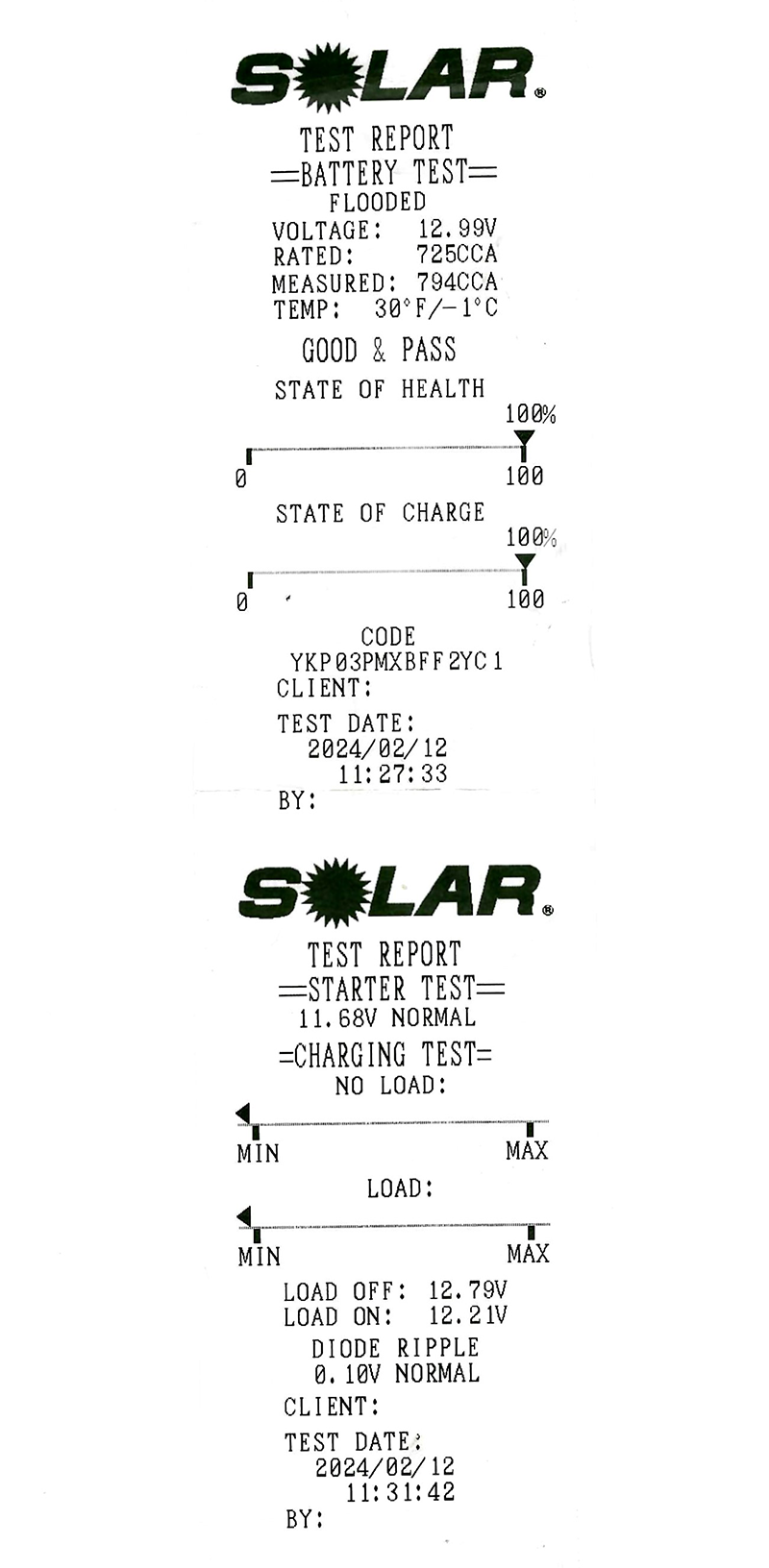

We began to perform a battery and charging system test, but the battery was too low of charge. Therefore, we charged the battery overnight. Once the battery was charged, we tested the battery and the charging system. The battery tested good, but the alternator failed the charging test. With a load the battery would only reach 12.2 volts. The alternator was not charging and when electrical loads were applied the voltage would continually drop. (Figure 5)

Figure 5

While the battery still had good voltage, we road tested the vehicle. The speedometer and odometer were indeed inoperative. The transmission shifted properly, and the shift-feel was good. The battery was running at about 11.8V so we had to make it a short road test.

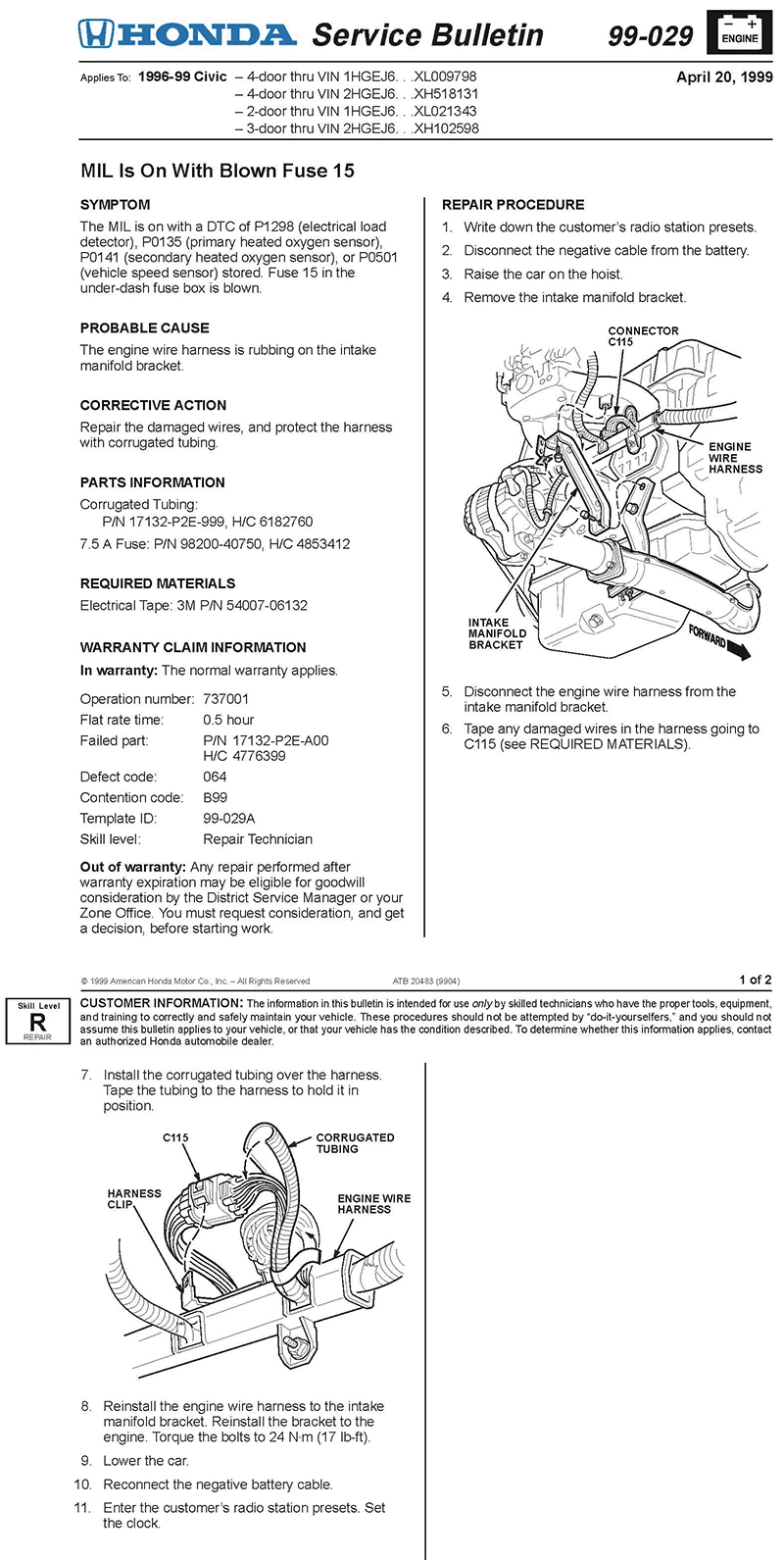

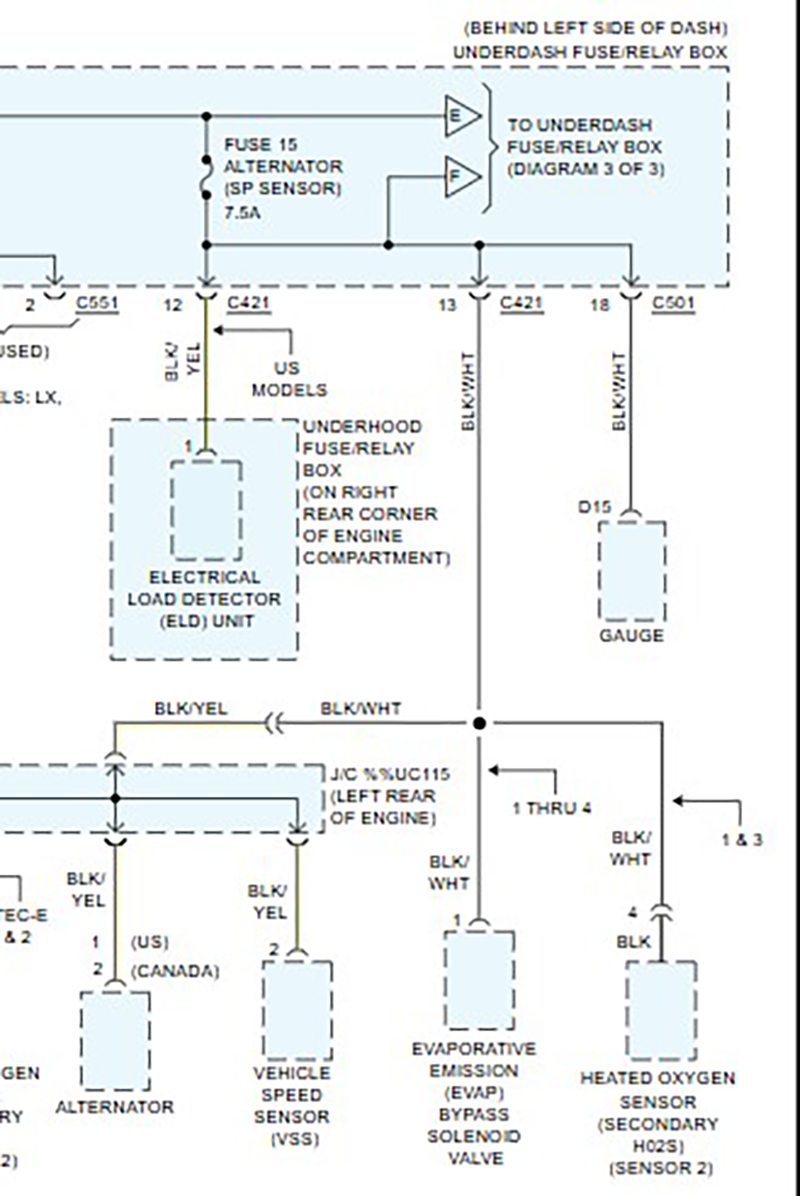

The battery and the alternator both looked new. We suspected that the alternator that was installed was malfunctioning. Someone had replaced these components recently. We did a scan of the vehicle's systems and there were DTCs stored: P1298 (electric load detector high input), P0135 (O2S 11 heater circuit), and P0141 (secondary HO2S (sensor 2) heater circuit). All these codes were cited in Honda TSB 99-029 which I found with a bulletin search. (Figure 6)

Figure 6

What about the inoperative speedo? The VSS and the O2 heater circuits are powered by the same fuse related to P1298, so we suspected a blown fuse number 15 in the dash panel fuse box. Upon investigation, the #15 fuse (7.5-amp) was missing. This missing fuse could be the fix to the issues that are occurring at present. Why would someone remove that fuse? (Figures 7 & 8)

Figure 7

Figure 8

We installed a new 7.5-amp fuse where the fuse was missing, cleared the codes that were stored, and drove the vehicle. The alternator was now charging correctly, the O2 codes had not returned, and the speedometer and odometer were now working correctly.

The customer was advised of the TSB for harness chaffing, and we referred the customer to the dealer for repairs based on the goodwill policy mentioned in the TSB. At this time the vehicle was working correctly, but the harness was likely shorting to ground and blowing the fuse, which might explain its prior removal. The customer was pleased that we got to the root of the issue and planned to get the rest of the issue resolved at their dealership.

Certified Transmission

Certified Transmission