While it's common for a customer to bring us a vehicle with a single, specific complaint, we often find more than one problem when getting into the diagnosis of their original concern. The owner only knows one thing; they want the vehicle to run and operate properly. It's our responsibility to identify and execute a complete repair and convey what that entails to the customer.

Our first vehicle was a 2006 Ford F–150 equipped with a 5.4L engine, 4R75E transmission, and 434,000 hard–use miles. The customer's concern was simple; overdrive light was flashing, hard shifts in every gear, and the transmission malfunction indicator is illuminated on the dash. The customer provided the following trouble codes to us: P0705 (transmission range sensor circuit fault), P0748 (pressure control solenoid electrical), P1702 (transmission range sensor circuit intermittent fault). He told us the transmission had been rebuilt last year and had never worked correctly since that time.

I began the evaluation by checking the fluid level and condition to see that it was full and fair. A quick code scan before the road test revealed that a lot more was going on with this vehicle beyond what the customer shared with us. A laundry list of engine performance codes was stored in memory along with the three that were provided by the customer. During the road test, I was able to confirm the hard shift in every gear complaint but also noted engine misfires present and a lack of power once warmed up. During the under–vehicle inspection, it appeared that the range sensor had been replaced at some point.

At this point I recommend electrical testing to pinpoint the cause of our range sensor and pressure control problems. Our service writer explained in detail that there was more than one issue on the vehicle and that it would take extra time to pin down properly. The customer approved the additional diagnostic time, so I rolled up my sleeves to dig into it.

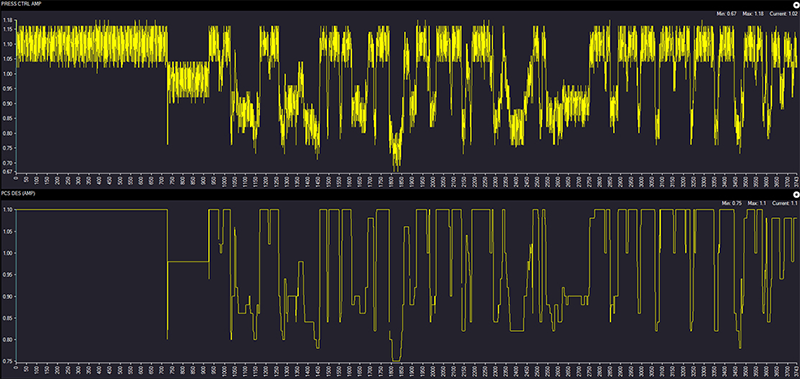

I started with the range sensor codes. After checking power and ground down to the connection, range sensor voltages seemed normal but were out of sequence per the wiring schematic. TR2 should have had 12v present, but only showed 5v. TR3A showed 12v, but should have been 5v, which was puzzling. I pulled the wiring loom off and discovered the pigtail for the range sensor had been replaced as well. I removed the face of the connector and swapped pin 3 and pin 5. (Figure 1)

Figure 1

Checking from the PCM connector down to the range sensor connector proved the wires were simply in the wrong position inside the connector. I cleared the codes, and the range sensor codes never came back during the road–test, but I still had the hard shifts and overdrive light flashing. Now to move on to our apparent pressure control issue.

I began by disconnecting PCM connector C175T and checking for voltage on pins 38 (vref), 37 (ssb), 36 (tccs) and 39 (epc) with the key on. Pins 38, 37, and 36 all read battery voltage. When I got to pin 39, I found around 4v present. With that information in mind, I load–tested the wire from the transmission connector (pin 6) to the PCM (pin 39) to verify that I didn't have a high resistance in the wire between the two. I suspected the internal harness of the transmission had failed, but with the mileage of this vehicle, it was up to the customer to decide how further into this he wanted me to go.

Since the transmission had been rebuilt recently the customer decided to have us replace the internal harness and pressure control solenoid before committing to a fully remanufactured transmission. After replacing the internal harness and EPC solenoid, the transmission worked perfectly, and the customer was pleased that we saved him the additional expense.

Our next vehicle was a 1999 Chevrolet Express 2500 equipped with a 5.7L engine, 4L80E transmission, and 268,000 miles on the odometer. The customer's concern was the engine stalling at stops and transmission shifting hard through gears. The transmission had been rebuilt and started having problems eight months after that repair. The shop that had originally performed the transmission work attempted to diagnose these issues and had replaced multiple components before ultimately replacing the engine without solving the issue. Oops.

Upon starting the initial evaluation, I found the transmission fluid level low and in fair condition. A code scan revealed P0748 (pressure control solenoid electrical) stored. I pulled the vehicle into my bay to check for leaks before beginning a road–test. As I pulled onto the lift and stopped the engine chugged and stalled out. During the under–vehicle inspection, I did find the transmission pan leaking. At this point, I stopped to get with my service advisor because there was no leak concern noted by the customer. The advisor called the customer to confirm he had been adding fluid to the van. I suspected that the stalling was caused by the low fluid condition present, so I topped off the transmission fluid and started another road–test.

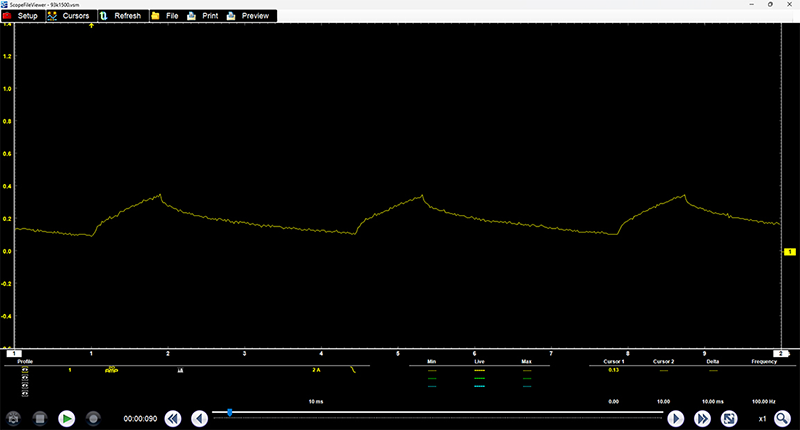

Even with the transmission fluid full the engine still wanted to stall when coming to a stop. When upshifting, the transmission shifted more firmly than it should with normal driving, but the shifts felt normal with heavy acceleration. When monitoring the pressure control amperage on the scan tool it seemed to be normal (around .7 to 1A). (Figure 2)

Figure 2

At this point it was clear to me that I may have more than one problem to diagnose on this vehicle. Our advisor got additional time approved, and I began my research.

Due to the hard shifting and P0748 code, I began by checking the circuit for the pressure control solenoid. When I inspected the PCM I had noticed that someone had spilled brake fluid on it when filling the master cylinder. I first checked the resistance in the circuit at the PCM C3 connector from pin 6 to pin 16 and found 4.5Ω, which is within specification. I then load–tested the wiring to make sure it could handle the current from the solenoid before putting my amp clamp on the circuit to prove what I already suspected. The current probe showed less than half an amp when our scan data showed around 1 amp. The pressure control solenoid was working properly, but the PCM had failed to control it properly. (Figure 3)

Figure 3

The customer was advised of our findings that the vehicle required a PCM replacement in order to correct the hard shifts, but if the engine continued to stall, the transmission would also need to be replaced.

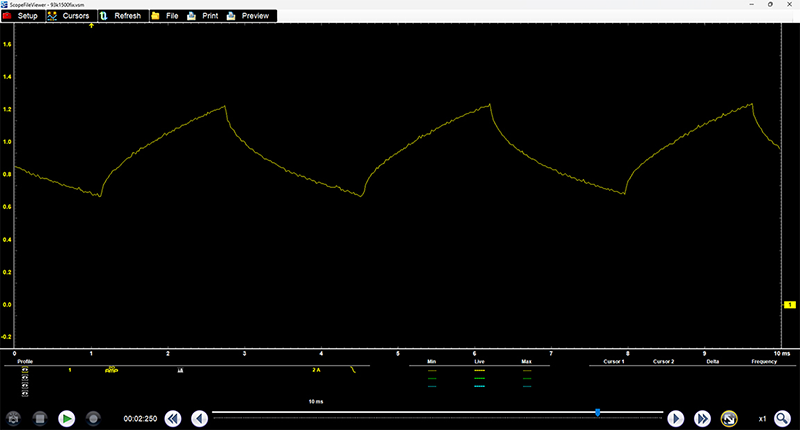

I replaced the PCM and that corrected the amperage issue to the EPC. (Figure 4).

Figure 4

Unfortunately, an internal transmission problem was evident after the PCM replacement, so we replaced the customer's unit with our remanufactured transmission.

After struggling with other shops to get the 'Job Done Right', our customer was very happy to get the van back in working order except for one issue; now the headlights didn't light up! After a few minutes of checking power and ground to the headlight connectors, we were able to confirm the sealed assemblies needed to be replaced and the van was ready to get back to work!

Certified Transmission

Certified Transmission