A customer came to our shop with a 2010 Ford Fusion equipped with a 2.5L engine and a 6F35 transmission. The customer had a concern of the vehicle banging into drive and reverse intermittently, along with lack of acceleration when this would occur. On my initial inspection I found the fluid full and in fair condition, with no leaks seen anywhere. The computer had a history of code P0754 (shift solenoid "A" intermittent), but no active codes. I test drove the vehicle while monitoring commanded gear, torque converter slip RPM, output and input speeds, shift solenoid "A" command, and shift solenoid "A" voltage. The transmission operated as designed without setting any fault codes or having any noticeable harsh engagements.

We notified the customer that I would need to spend more time with the vehicle to try and recreate the fault conditions. This would help me determine what route we needed to take with the diagnosis. I did some research and found the solenoid should be off in park, reverse, and neutral. It is only commanded on from first through fourth gears, and then is turned back off in fifth and sixth gears. I then took the vehicle on an extended test drive of 30 miles trying to get the vehicle to shift as much as possible from fourth to fifth gear. I wanted to see if the solenoid was staying on when it should shut off, or if it was turning off when it should be on. Again, the vehicle operated perfectly with no faults. Using the scan tool, I was also able to command the solenoid off and on and could hear the click from the transmission, showing us that the solenoid was electrically working.

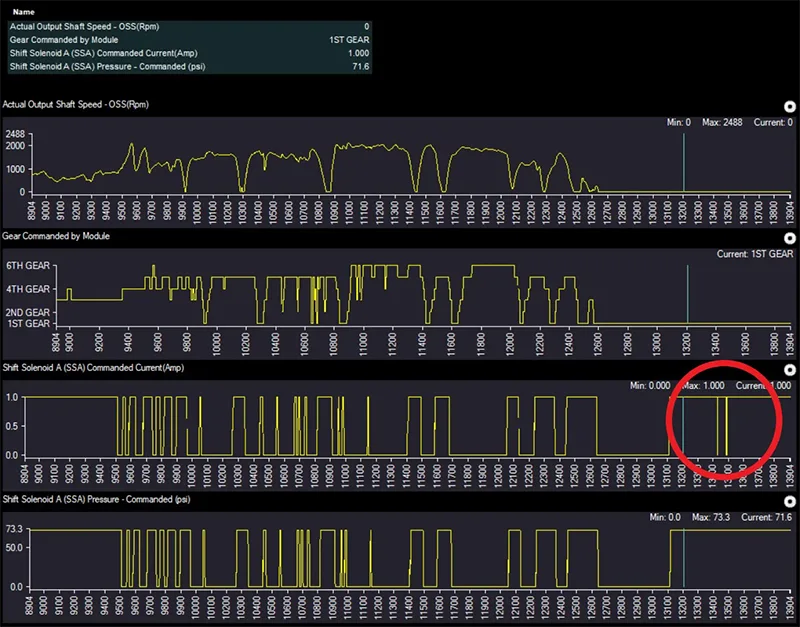

I then wanted to find out from the customer when exactly the vehicle was acting up. I wanted them to talk me through their drive each day to try and find a pattern. Well what seemed intermittent to them actually had a pattern they just hadn't noticed. It would sometimes act up as soon as the left their house, only after they would start their car and let it warm up. If they started out cold it would drive okay. When it acted up while they were driving, it would be in stop and go traffic. If they were on the open roads with no stopping it would seem to work fine. I was able to see a pattern. If the vehicle could run with little to no under-hood cooling from air movement, it would start to act up. I ran the vehicle in the shop since I wanted to see how long it would take for the solenoid to act up, so I chocked the tires, set the parking brake, and let it idle in gear while monitoring shift solenoid "A". Within 15 minutes the solenoid would start cutting out and the vehicle would set the P0754 fault and go into fail safe. I had finally recreated the circumstances that caused the vehicle to act up. Now I had to be quick with my testing so I would not lose my conditions. (Figure 1)

Figure 1

I started with checking continuity from the PCM through the transmission. I found no open in the circuit. I tried wiggling all connections to see if I could get the connection to break. The circuit held and never went open, and it was showing 5.19 ohms for the transmission temperature of 163?F, which according to Ford specs was correct. I also did a load test with a headlight to see if it could maintain voltage, and it did. I then proceeded to check all connections for fitment and to make sure there was no moisture or corrosion. I found that pin 22 on the C1520A trans-axle vehicle harness was recessed compared to the rest of the pins. When I checked it, I found I could push it up and down and that it wasn't fully snapped into the connector. I assumed this was my problem and figured it was just barely making connection, and when the harness would get hot, it would start to lose connection. I reseated the pin and made sure it had no movement; I then cleaned the connector and applied dialectic grease. In my mind I was sure I had found the problem and was sure the issue would be fixed. I reconnected everything and set the vehicle up to run again, in gear, while monitoring the problem solenoid. Within ten minutes the solenoid was cutting out and the vehicle went into fail safe again.

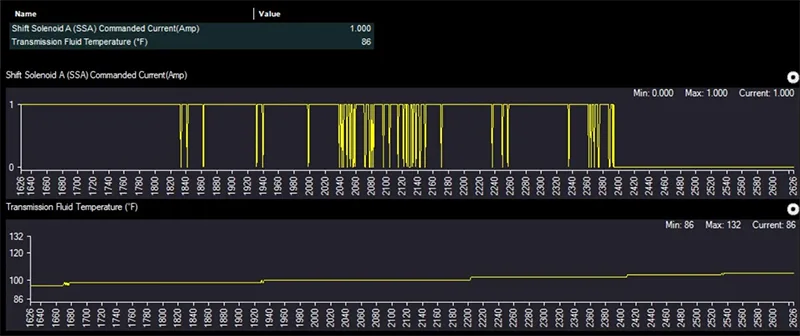

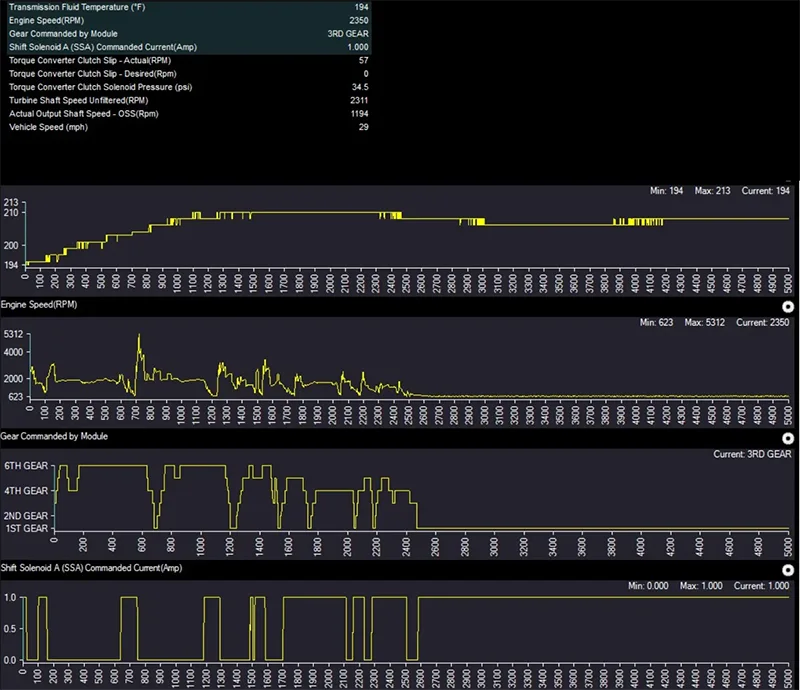

I was at a loss; everything had checked out! The circuit was good and I could command the solenoid and hear it activate. The vehicle performed great until it got hot under the hood. The only thing left was the computer. It was the only other thing that made sense. I then let the vehicle cool back down and made sure it was operating as it should. I applied heat directly to the computer using an industrial heat gun to raise its temperature quickly. Within a few minutes the solenoid started cutting out. (Figure 2) I had found the culprit! I replaced the computer and programmed it to the vehicle using FJDS. I performed my test one last time. I once again ran the vehicle, in gear at the shop, while monitoring the solenoid. After 20 minutes of continuous running, I had no fault. I test drove the vehicle through neighborhoods trying to maintain low speeds with as much stopping as possible. The vehicle performed normally. (Figure 3)

Figure 2

Figure 3

We delivered the vehicle to a thankful customer that was pleased and excited that they didn't need a new transmission. The difficult part about diagnosing a defective controller is that it's essentially a black box; there is no information regarding the internal circuitry, so you're left with acting on a hunch and trying to recreate an environment as I did, or just taking an expensive chance by replacing it. Knowing the primary trigger of the issue is the key to a successful diagnosis.

Certified Transmission

Certified Transmission