Quite a lot has been been written and many technical classes have been put on regarding the General Motors 8L45/8L90 family of transmissions. We are now seeing opportunities to put that information to use. The vehicles equipped with these transmissions are beginning to trickle into our shops as they are beginning to fall out of factory warranty. Many GM vehicles utilize these transmissions from 2015 to present.

Our first vehicle to come in with 8L90 problems was a 2016 GMC Sierra 4x4. The truck had 103,000 miles on the odometer. The customer's complaint was that the vehicle had a "shake" feeling below 70 miles per hour. He also that there was a "rumble" feel occasionally.

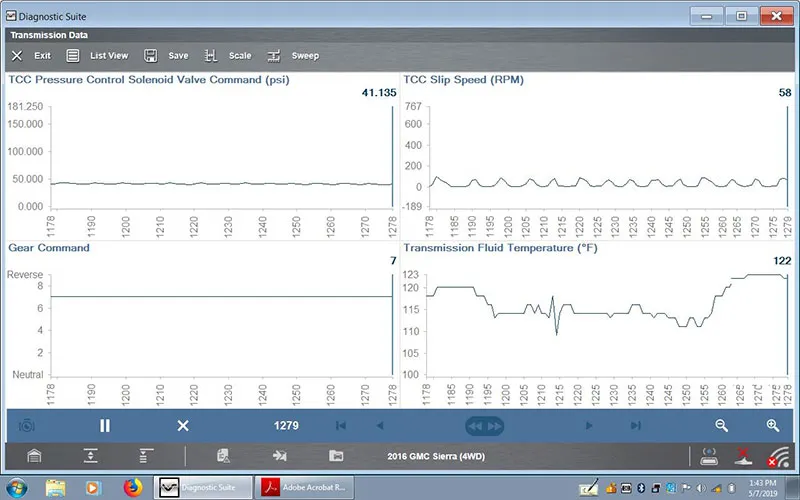

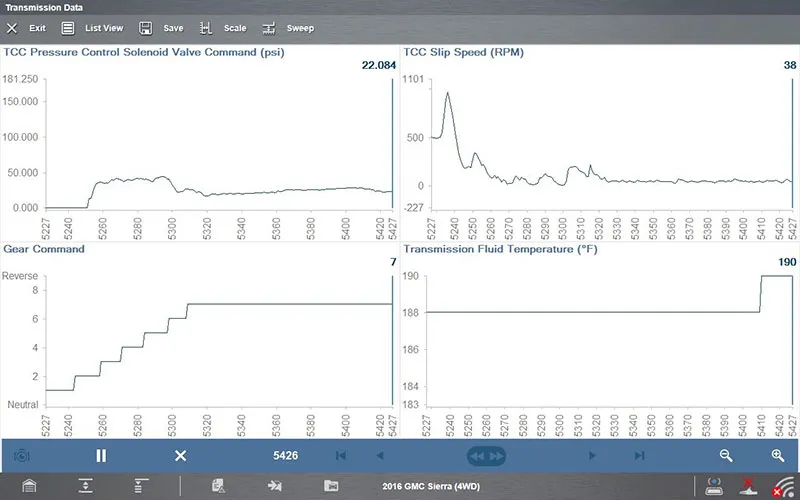

When evaluating the vehicle I noted that there was a P0711 (transmission fluid temperature sensor "A" circuit range/performance) code present. The transmission fluid was dark red with a slight burnt smell. During the road test I was able to reproduce the customer's complaint. I experienced a repetitive, systematic vibration and droning sound throughout the vehicle at highway speeds. I was able to capture the issue using the scan tool.

Figure 1

This photo illustrates (Figure 1) TCC slippage and the TCM attempting to compensate/correct for it. The rhythmic shudder I experienced coincides with TCC slip speed captured with the scan tool. The transmission fluid temperature shown on the scan tool also explains the P0711 code. A sudden change in fluid temperature (50?F or more within 8 seconds) will cause P0711 to set. Obviously the transmission fluid temperature reading on the scan tool was unstable, so an electrical system analysis was performed to ensure battery and alternator integrity. Excessive AC ripple can play havoc on any electronically controlled transmission. A pan inspection was performed; evidence found in the pan along with the fluid condition had eliminated the possibility of trying to flush out the fluid with the Mobil 1 LV product, per a GM TSB.

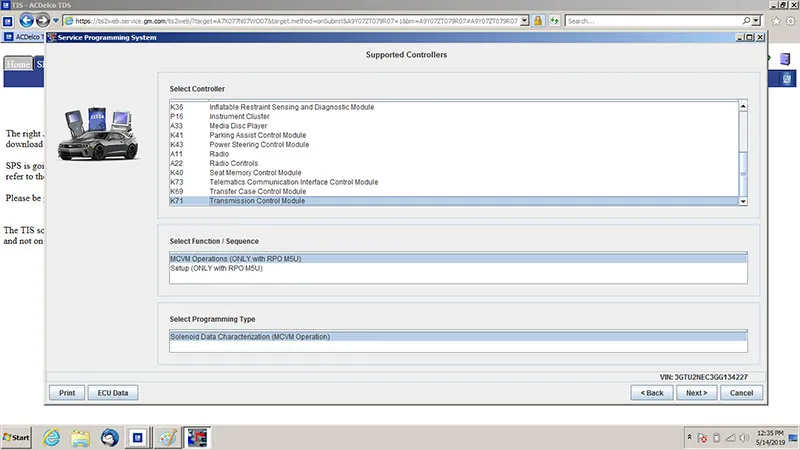

At this point the customer agreed to replace the unit per our recommendation. After the unit was installed, solenoid valve characterization reprogramming had to be done. This is required when replacing 8L45/8L90 transmissions, and accomplished through General Motors' TIS2Web Service Programming System (SPS). When performing solenoid valve characterization reprogramming, it is crucial to have a good clean power source connected to the vehicle's battery and have all vehicle accessories turned off, as with any other programming procedure. Solenoid valve characterization reprogramming is fairly straightforward. After logging into the SPS website and purchasing a subscription for programming the vehicle you are working on (programming subscriptions are VIN specific), SPS will verify the vehicle/VIN you are working on. After SPS completes the verification, you will be directed to the screen shown in figure 2:

Figure 2

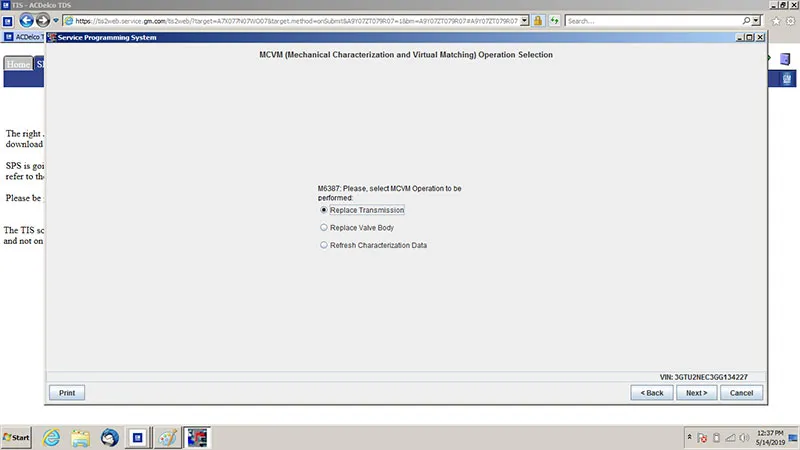

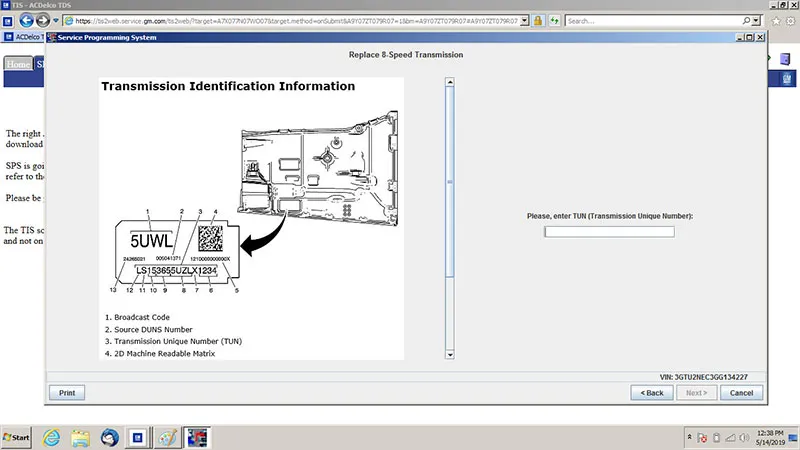

Highlight "K71/Transmission Control Module" in the "Select Controller" area. Then select "MCVM (Mechanical Characterization and Virtual Matching) Operations" in the "Select Function" area. Verify that the RPO code given coincides with the vehicle you are programming. Finally, be sure you select "Solenoid Data Characterization" in the "Select Programming Type" area at the bottom of the screen, and click "next". The next screen will be the "MCVM (Mechanical Characterization and Virtual Matching) Operation Selection" screen (figure 3). Here you will be prompted to select what operation to be performed. In this case I chose "Replace Transmission", as the unit had been replaced. Clicking "Next" will move you to the next screen (figure 4). Here you will enter the TUN (Transmission Unique Number).

Figure 3

Figure 4

This number can be found on a sticker on the right side of the transmission as seen in the "Transmission Identification Information" section of the screen. After entering the TUN and clicking "Next", SPS will then begin the programming operation and prompt you when the process is completed. SPS seems to be user friendly regarding this process. I had no issues getting through it for the first time. At this point it is also recommended that the ECM (Engine Control Module) is updated to the latest calibration. The ECM on this particular truck happened to be up-to-date.

The next step in the process is to perform a "Fast Learn". This clears all adaptive values in the TCM. Using your scan tool, follow the on-screen instructions precisely. Keep in mind that if at any time in the process, there is an interruption; you could experience a false neutral condition with the transmission. If this happens, you will have to disconnect and reconnect the TCM to correct the issue.

On the initial road test after installation, I experienced very minimal flaring during shifts. This flaring cleared up within a few miles of stop-and-go driving. This may vary from vehicle to vehicle. When rechecking the fluid lev-el, the transmission fluid level must be brought up to 194?F to ensure that the thermal bypass valve is open, if so equipped. Allow the fluid temperature to cool back down to 95-113?F. With the engine running, remove the transmission oil level plug from the transmission pan. At the correct level, fluid should drip from the check plug hole.

On the final road test, I monitored "TCC Slip Speed" and TFT (Transmission Fluid Temperature) with the scan tool. As you can see in (figure 5) the TCC slip speed is smooth and now normal. The TFT was stable as well. A post scan also confirmed that no codes reset.

Figure 5

Other than routine maintenance, this was the first major 8L90 issue we have dealt with. In the near future, I foresee many more 8L45/8L90 transmissions showing up. The torque converter issue we experienced on this vehicle is a problem that many dealerships have already encountered. Don't be surprised to see these vehicles begin to show up at your shop, if they haven't already.

Certified Transmission

Certified Transmission