Recently, we had the opportunity to work on a couple of GM 10L1000 transmissions. Although we don't currently produce this unit, we assisted some partners of Certified Transmission who requested our expertise.

Case 1: 2024 K2500 6.6L GASThe first case involved a 2024 K2500 6.6L GAS with only 35,000 miles. The truck had been sitting at a local dealership for two months, awaiting a new valve body that was on national backorder. The customer, facing the prospect of trading in a broken vehicle at a significant loss, sought our help.

The dealer had diagnosed the issue as a DTC P0747 (Transmission Control Solenoid Valve 1 Stuck On) and recommended replacing the control valve body. However, there was no ETA for the part. Our Head of R&D asked if we could investigate it, and I agreed; I was eager to learn something new.

Upon arrival, the truck initially operated fine but exhibited issues after warming up. During the 6-7 shift, the transmission would bind up momentarily, repeating three times before going into failsafe mode (5th gear). This felt similar to the DTC 46, which is a 3-4 shift abort on an A604. This is a problem some of you might remember.

We checked for valve bodies at dealers nationwide, but none were available. Everyone we contacted said the parts were reserved for trucks already in their shops. With no other options, we decided to disassemble the valve body and perform vacuum checks to diagnose the issue ourselves.

During our inspection, we found that the "Feed Limit Valve Low" vacuum checked at 5 inHg, while the "Feed Limit Valve High" checked at 16 inHg. This discrepancy indicated a problem with the valve. We installed a valve body kit to address this issue, though I have concerns about its long-term viability. I suspect that companies like Sonnax and TransGo are already working on more permanent solutions, as research indicates that this appears to be a widespread issue. Despite these concerns, we managed to get the truck back on the road for the customer, who was relieved to have his vehicle operational again.

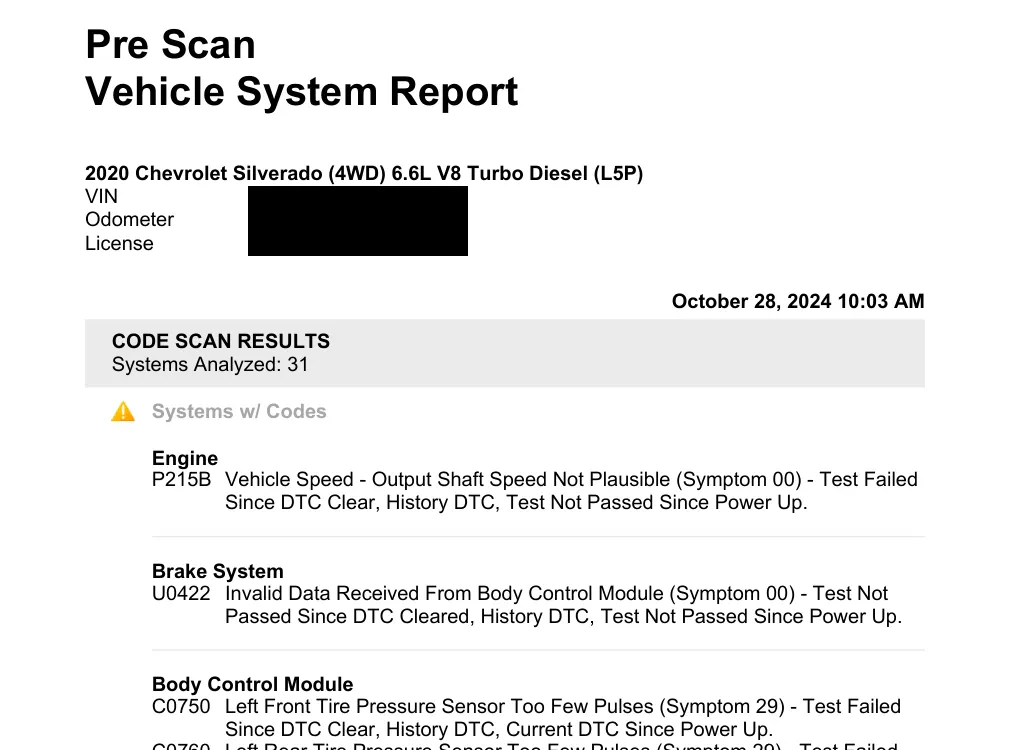

Case 2: 2020 K3500 6.6L DieselThe second case involved a 2020 K3500 6.6L Diesel with over 80,000 miles. This truck presented different issues, including shift concerns, a strange reverse engagement, a slide bump or double bump on the 3-4 upshift, and downshift issues with the 5-3. It also had a stored code P215B (Vehicle Speed Output Shaft Speed Not Plausible) on the engine side, which we couldn't duplicate or reset. (Figure 1)

Figure 1

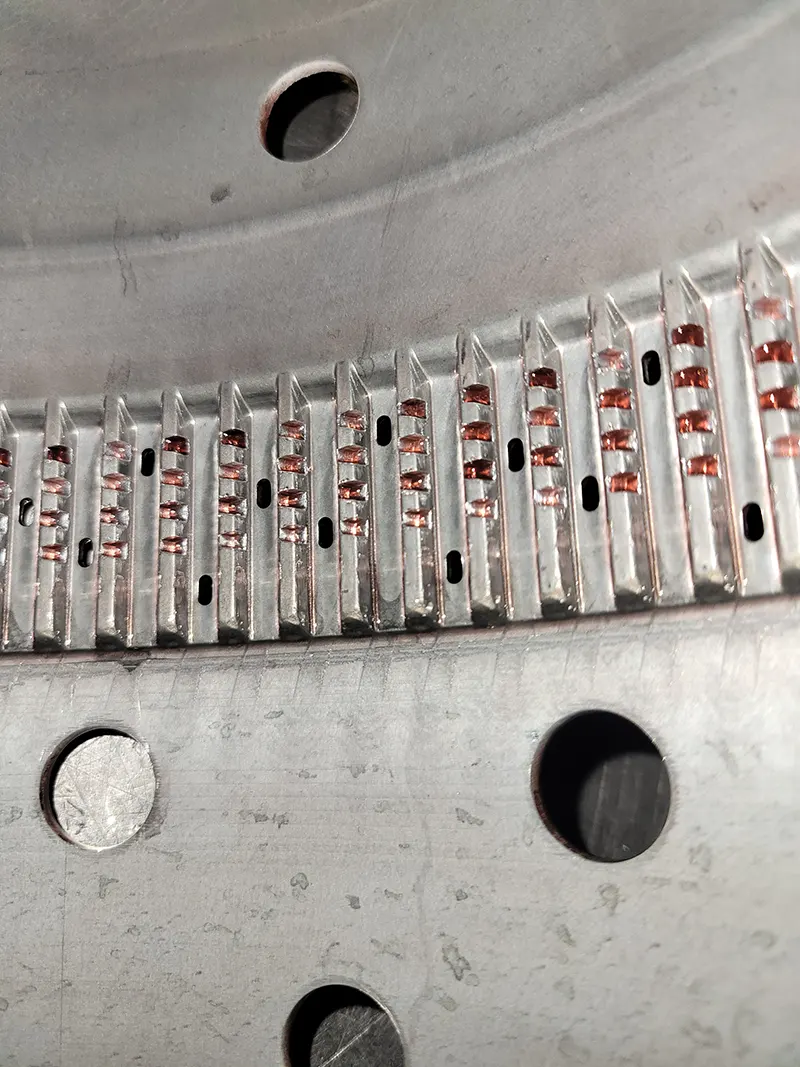

After conducting a thorough Certi-Care evaluation, we found too much debris in the pan to justify going into the valve body. Upon disassembly, we discovered significant wear on the output carrier internal gear transfer shell, similar to issues seen in other RWD 10-speed transmissions. The clutches had almost worn through the shell, a problem reminiscent of the 10R80's shell also known as, "The Trash Can." (Figure 2)

Figure 2

We sourced the necessary parts which took about two weeks to arrive. Reinstalling the unit proved challenging due to clearance issues with the output shaft and torsion bar crossmember. GM's procedure suggested removing a rubber plug at the top of the transfer case for clearance, but we couldn't get enough space. We ended up loosening the torsion bars and removing the crossmember, a workaround that worked for us but might not be the official solution. As we gain more experience with these units, I'm sure we'll refine our approach.

Despite these challenges, the installation was otherwise straightforward. Programming the TUN was similar to the 8L90. The fast-learn adapt process requires the transmission at 167° F at a minimum in order to run. After the clutch purge process, the unit entered the "Drive Calibration" portion of the routine, where it engaged gears quite aggressively, even more so than the AS69RC quick-learn. Fortunately, the unit required minimal drive relearning and performed well right from the start.

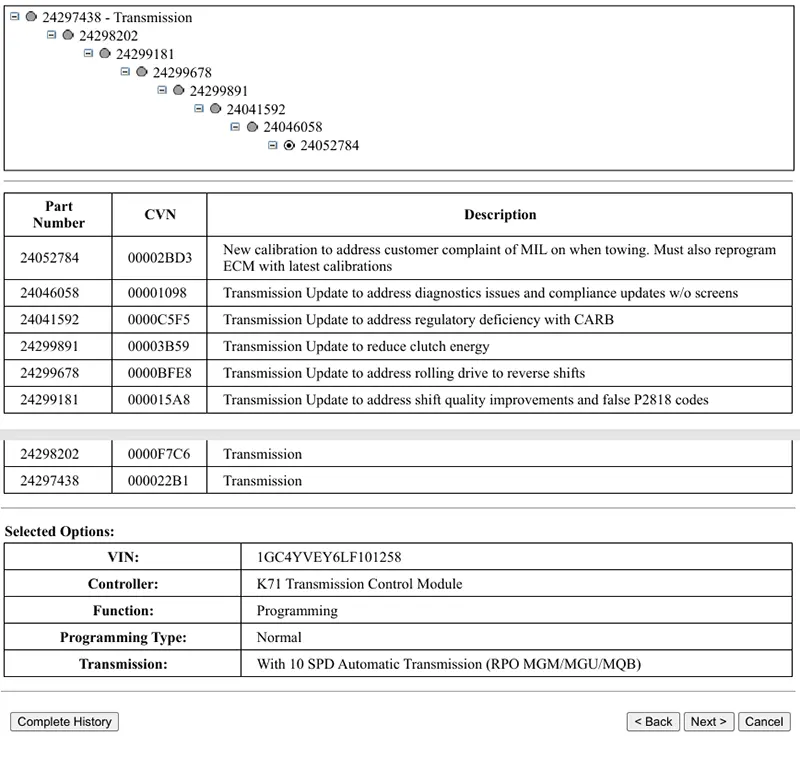

One crucial takeaway from this experience is the importance of keeping ECM/TCM calibrations up to date. The 2020 truck we worked on has undergone seven different calibration updates since it was put into service. Ensuring these updates are applied can significantly impact the performance and reliability of the transmission. (Figure 3)

Figure 3

Working on these GM 10L1000 transmissions has been a valuable learning experience. While the challenges were significant, our team was able to diagnose and address the issues effectively. The cases highlighted the importance of thorough diagnostics, the value of having a knowledgeable team, and the necessity of staying current with software updates.

As we continue to encounter more of these units, our procedures and techniques will undoubtedly improve. The lessons learned from these cases will help us better serve our customers and ensure their vehicles remain reliable and operational. Whether it's sourcing hard-to-find parts or developing innovative solutions to common problems, our commitment to excellence remains unwavering.

Certified Transmission

Certified Transmission