GM 6L Series

One of the most common complaints I hear from shops when trying to install a new GM TCM is, "The module will not communicate." While that might be partially true, by design they won't communicate until they are programmed. If programming fails, there will be an "E" code set which will help you get to the root of your problem. Most of the time this will require the programming event to fail three times before the code will set, so the easy first step is to let the programming fail three times and you should see one of these codes displayed. Some of the more common codes are:

- E6961 — "Unknown Error." This is more of just more of an informative code; try programming again to get a different E code. Do not shut the key off and do not start a new session; simply press "replace and program" again and see what happens.

- E4398 — "No Calibration Data." This does not mean the module is blank, but rather there is no information on the GM server for this VIN. Calling the GM tech line and having their techs look at your error should fix your problem.

- E4413/E4414 — "Calibrations marked with an asterisk are either newer than what is available in this release of tis2web or they are NON–GM calibrations." The most likely cause for this is aftermarket programming in the module. The solution is simple; press "replace and program" to go back to factory programming/ settings.

- E4491/E4423 — "Programing failed." Unless the failure was obvious (like the battery going dead, the OBD connector came unplugged, the internet failed, etc.), then I would attempt programming again. If programming still fails it would be time to start the basic diagnostic process checking power and grounds, etc.

The moral of the story is that if someone says their GM module failed to program it should be giving an E code. Once you know the E code you can start the diagnostic process of finding the cause. The number one rule I convey to customers is not to panic, because most of the time the error is caused by something simple.

GM 6L Series Confused for 8L Series

Another problem I see on the increase is programmers asking for a PUN and TUN on the 6–speed transmission. The most likely cause for this is selecting the wrong RPO code while selecting which module to program. If your tool is requesting a PUN and TUN for a 6–speed then you need to back out and select "K20/71 (ECM/TCM)" for sequential programming. The RPO code you want for a 6–speed is "Without RPO code M5U." By selecting "Without RPO code M5U", you can begin normal programming by selecting "Replace and Reprogram".

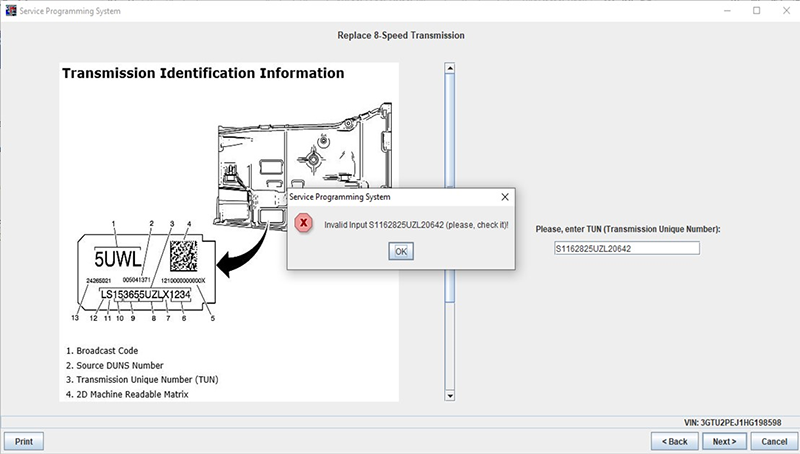

In addition, unfortunately the GM database isn't always accurate, and you may not have the selection "Without RPO M5U" displayed as an option. In this case, it would be helpful if it gave you error code E4398, but it does not. However, the fix is the same. A call to the GM tech line explaining there is no calibration data on SPS for a 6–speed which will point them in the correct direction and should have you back up and programming in no time. One more issue as far as the GM database is concerned, we have run into several of the PUN and/or TUN numbers missing from the database which also generates an error. This scenario will also require a call to the tech line and usually a photo of the VIN and of the tag with the TUN #. (Figure 1)

Figure 1

Ford 6R Series (early)

I field a lot of questions from customers seeking solenoid strategy and solenoid ID for early Ford six–speed automatics. The problem is, there isn't any. Evolution of the six–speed starts with the 2005 MY ZF6HP26 later becoming known as 6R60. These have an internal Mechatronic/TCM unit and no one–way clutch like the GM 6L80 has. No low one–way clutch meant that these early models could have extremely harsh 2–1 downshifts. There are software updates to help smooth downshifts, and bad coils (COP) (always look at #4 first) have been known to cause problems as well.

Nissan Programming

Programming Nissans can be a little problematic with some of the workarounds they have developed for aftermarket programming. NERS (Nissan ECU Reprogramming Software) is what some aftermarket programmers can use with a J2534 device. This does not have the functionality of a scan tool; it is just for reprogramming. NERS has had some issues with failed programming events that can result in a bricked ECU. While there is some technical support offered by Nissan, it is a very slow process. One of our locations took 18 days and multiple phone calls before they determined where the problem was, and even longer to fix it.

Consult 3+ RTR Software (J2534 hardware) also has some issues. One example of this is after programming you may be instructed to perform several on/off key cycles at ten–second increments. The RTR software sometimes does not recognize the key position and always shows the key off. If you are programming a lot of Nissans, I would recommend going with the full OE Consult 3+ software and a VCI3 interface to ensure trouble–free Nissan programming and avoid issues like this, and of course having the OE scan tool allows you to perform many other diagnostics/functions beyond the aftermarket. Consult 3+ is not available as a short–term subscription; one year is the only option and must be used with the VI3 interface, as it is not J2534 compatible. (Figure 2)

Figure 2

Nissan CVT and Ford

It is always important to remember that when you are entering in solenoid ID and strategy in a Ford TCM, or if you are initializing a Nissan CVT, this is not technically "Programming/ Updating." This process will not give you the current calibration update like it does on a GM. After the initialization of these transmissions, you will have more steps to take such as updating the TCM and clearing the KAM on a Ford. For Nissan, you will need to update to the latest calibration and reset the fluid degradation data.

Certified Transmission

Certified Transmission