In addition to the OEM-spec remanufactured transmissions we build, we also offer a series of heavy-duty transmissions available in three different stages. The subject of this article is in regard to the installation of our Road Ripper™ 3000 (stage 3 unit) in a 2005 Dodge 2500 Pickup equipped with a 5.9L diesel and a 618/48RE transmission. The vehicle had been in use for about a month when the customer returned with an issue that the transmission was stuck in gear and would not shift. We did not want any damage to occur by the customer driving the vehicle to our location, so we set up a tow to have the vehicle picked up.

During my initial evaluation, everything appeared to be normal. Prior to the road test I hooked up the scan tool so I could scan all the modules, and to my surprise there were no diagnostic trouble codes stored. at this point a road test was in order, and as I prepared the scan tool for monitoring I looked at the data menu and noticed the governor pressure was at 98.4 psi with the key on engine off (KOEO), and the transmission throttle valve actuator (TTVA) was at 99%.

This data appeared to indicate an issue with the electronic governor pressure system, so I installed a pressure gauge to the governor port and the indicated pressure was at 0 psi as opposed to the nearly 100psi that the scan tool showed. I test drove the truck and the governor pressure did not come off 0 psi regardless of speed (at least the speed I could get to when it is not shifting). Although the scanner shows 98.4 psi all the time and TTVA is always 99%, the transmission is in a default mode and the transmission won't shift out of 1st gear. After a short test drive I rechecked for codes and none were found.

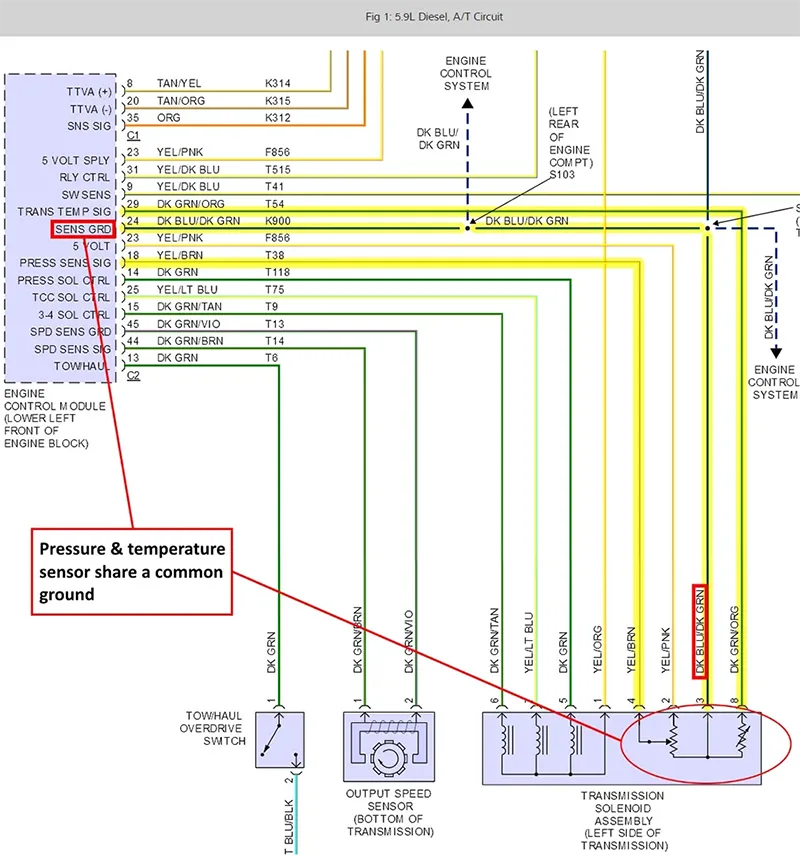

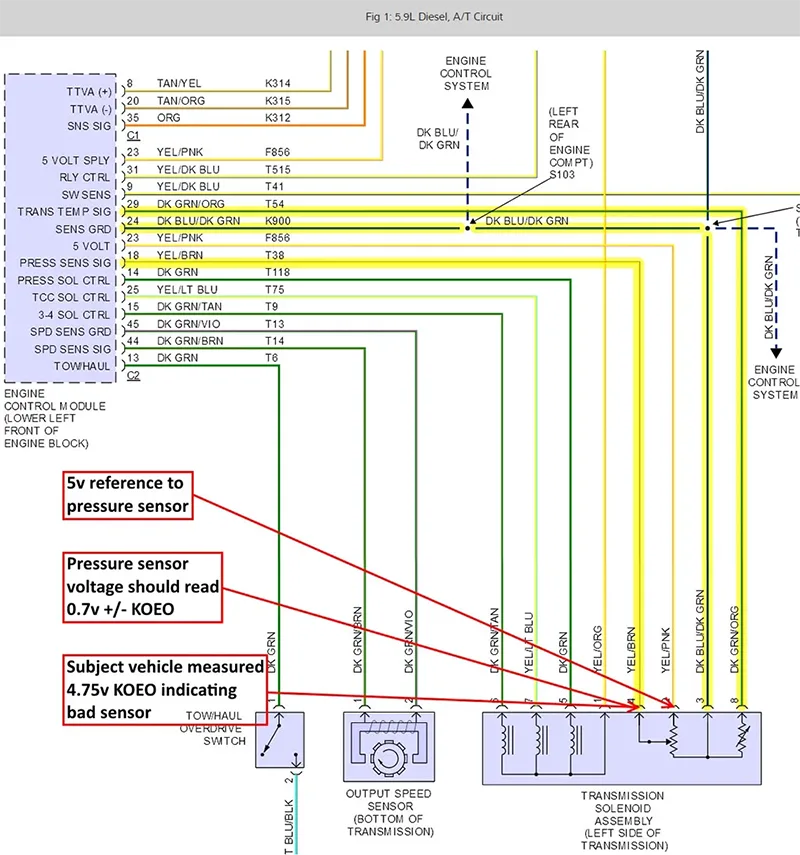

The reason there were no codes is because electronically the system was within correct parameters and I did not drive it far or long enough for it to set the P1762 governor pressure offset code. With this information we could conclude that the sensor was not giving us accurate information as originally suspected, but when I looked at the transmission temperature it was working correctly which told me the ground was intact for the sensor (Fig 1), since the pressure sensor and temperature sensor share a common ground. I checked the 5 volt reference at pin 2 (yellow & pink wire) and the voltage was correct. I then checked the sensor signal wire at pin 4 (yellow & brown) wire, and it read 4.75 volts which is very near reference voltage (Fig 2). The correct reading should be about 0.7 volts KOEO. The pressure sensor works similar to a throttle position sensor, except it uses fluid pressure to change its voltage output instead of a mechanical device.

Figure 1

Figure 2

At this time I determined we would need to check the components inside the pan. When I pulled the pan everything looked good and nothing abnormal was found. I did a visual inspection of the internal wiring and everything looked in order. We keep the sensors in stock at the store, so as a quick test, I plugged a new sensor in and the scanner immediately showed 0 psi for governor and the TTVA went to 0%. I plugged the old sensor back in and reading went back to 98.4 on governor and 99% TTVA. I was able to see a change for the better and then to verify the part I was replacing was definitely faulty.

I replaced the governor sensor, installed the pan and went for a road test. The governor pressure was now correct and transmission is shifting great again. Problem solved, or so I thought. Remember when I said earlier this is a Road Ripper™ 3000? Whenever there is a warranty issue, we submit a claim to our warranty department which reviews the concern and makes the recommendation for repair. Our warranty technician reviewed the repair and sent a message back stating since this is a Road Ripper™ 3000 unit, and therefore requires a special high-pressure sensor. The OE-style pressure sensor would work, but eventually the diaphragm will not survive with the higher pressures the Road Ripper™ 3000 is set up with.

We ordered a high pressure sensor from Rostra, and once the sensor arrived I realized how to tell a high-pressure sensor from a stock (OE) sensor. The stock sensor is all black, but the high-pressure version has a white cover on it (Figs 3&4).

Figure 3

Figure 4

Had we installed the OE-style sensor, the transmission would have worked for a while, but for how long is hard to tell. Thanks to our knowledgeable technical department, they were able to let us know about the discrepancy before we delivered the vehicle to the customer and had a potential governor issue down the road. This is another example of a system of checks and balances to ensure a positive customer experience, and when several people are involved there is a better chance something won?t be overlooked.

The repairs were completed, pressure testing and road testing were completed, and the vehicle was ready to be returned to the customer with the confidence that we had fixed it right, the first time.

The takeaway from this experience highlights the need to identify any special circumstances that may impact the overall quality of repair. While the diagnosis was routine and basic, overlooking the fact that this high-performance unit used a non-OEM spec part could have created a comeback situation down the road. An effective check-and-balance system saved the day on this one, and will again for a future day.

Certified Transmission

Certified Transmission