A 2001 Chrysler 300M came into our shop with concerns of a check engine light and the transmission would quit shifting. We had installed one of our remanufactured transmissions ten months prior, with warranty coverage. Doing an initial check everything seemed to be in order with the full and clean, wire connectors were secure, and harnesses routed and secured properly. An initial code scan showed a P1776 (Solenoid Switch Valve (SSV) Latched in L-R Position) and P1784 (L-R Pressure Switch Sense Circuit) stored in history. An initial test drive of 12 miles didn't duplicate any condition and it was apparent I would need to set aside time for a longer test drive.

This transmission family uses the L-R solenoid to control both the low reverse clutch and the torque converter clutch through a switching valve in the valve body. It redirects the fluid pressure when out of first gear when the transmission is in 2nd, 3rd, or 4th gear, and the L-R pressure switch goes low when the L-R solenoid is commanded for torque converter clutch (TCC) apply. The transmission control module (TCM) sees potential for unwanted application of the L-R clutch creating a bind-up condition and disables the L-R-TCC apply and stores the code P1776.

The P1784 code is set if the L-R pressure switch is either open or closed at the wrong time in a given gear.

With this information in mind, I set up the scanner to monitor the pressure switches and solenoid apply data and went for a road test. After 40 minutes of highway driving the check engine light came on and we also lost TCC application, and when I slowed the vehicle, the transmission defaulted to 2nd gear only with the P1776 code set. With a key cycle and the code cleared I drove the car another 40 minutes without any faults reoccurring.

Back at the shop I inspected all the connectors, terminals and harnesses to the solenoid and pressure switches. A static (with wiggle) resistance test of the circuits didn't reveal any problems, so I decided to replace the valve body and solenoid pack. Because this transmission has been out of production for several years, parts are scarce and new solenoid packs are nonexistent. The valve body and solenoid pack were removed and tested with no problems found, so the original solenoid pack and a different valve body were reinstalled. With the transmission warmed up to operating temperature and fluid level correctly set, I went out for a test drive without any fault conditions. After an overnight cool down, I went for a drive keeping it at 40-45 MPH where the TCC cycles on and off frequently, after 5-6 cycles the P1776 reset. I cleared the code, cycled the ignition and drove with the same conditions 30-35 minutes without any problems or code reset.

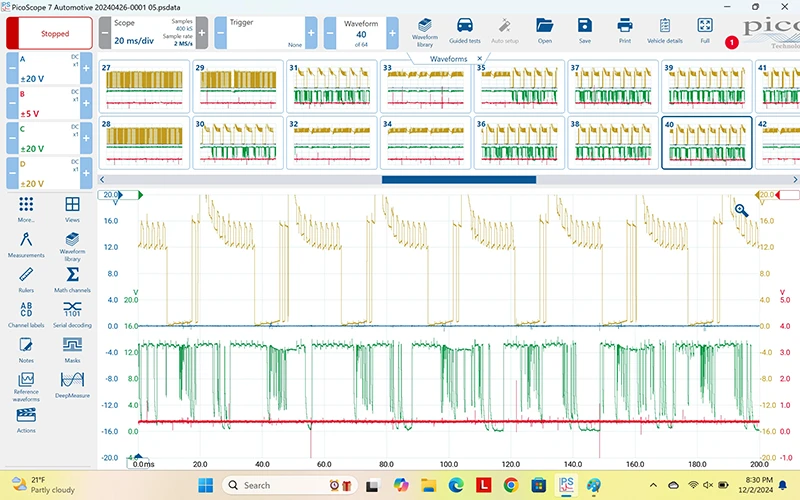

I decided it was time to connect my oscilloscope and try to pinpoint the problem. I connected channel A (blue) to the 2-4 pressure switch, B (red) 2-4 control, C (green) L-R pressure, and D (gold) L-R control. Again, from a cold start after a few TCC cycles the code reset with the L-R pressure voltage dropping low during the L-R solenoid partial apply as shown in figure one. (Figure 1)

Figure 1

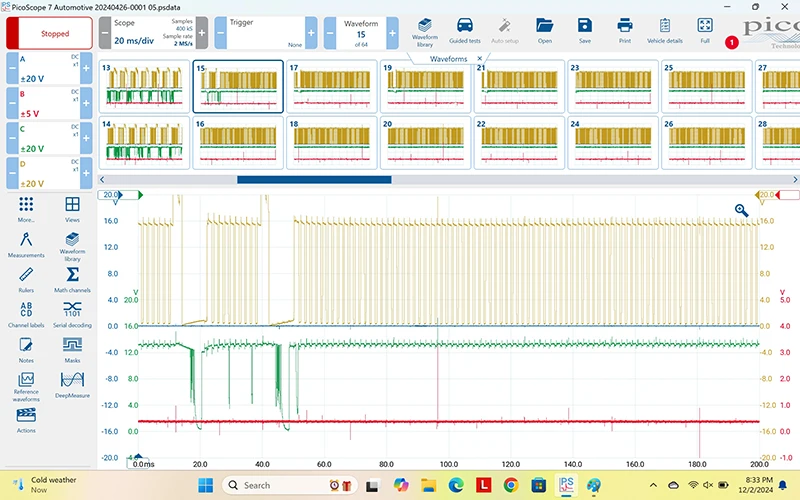

I could also see that the pressure circuit was spiking during partial apply on earlier applies, but not quite as low; during full apply it stayed high. (Figure 2)

Figure 2

The longer I drove, the less drop I had in the LR pressure signal. What the heck? Next, I installed a pressure transducer at the L-R pressure channel to monitor the actual pressure to the L-R clutch and connected it to scope channel B (red), eliminating the 2-4 control pattern. Two more drives from cold start resulted in the same results with the code only setting once per drive cycle, and no rise indicated in the actual L-R pressure when the pressure signal did spike low. After rechecking circuits and controls outside the transmission and with the solenoid pack not available it was decided to replace the transmission assembly with another reman unit that had been tested good on a dyno.

Once the replacement transmission was installed, I went for another drive duplicating the earlier conditions with repeated TCC cycles. Although it seemed to warm up more before the fault occurred, it did reset P1776 and now once cleared it would reset on the next TCC command repeatedly.

I reconnected the scope, but the channels were changed to A (blue) L-R pressure, B (red) L-R command, C (green) 2-4 pressure, and D (gold) L-R transducer, with the scope patterns being like the capture from before. Just to eliminate external possibilities a used PCM was installed with no change, and the wire harness was removed and inspected thoroughly with no problem found and no change in the condition.

Feeling that I was developing paralysis from analysis, I needed to step back and re-examine the process.

When studying the scope captures again, I found that while the 2-4 solenoid was in partial apply there were some spikes in the L-R pressure sensor circuit similar to when the L-R is commanded on; the L-R control circuit was also pulling low during the 4th gear apply, although there was no actual pressure indicated and no command to the LR solenoid. (Figure 3)

Figure 3

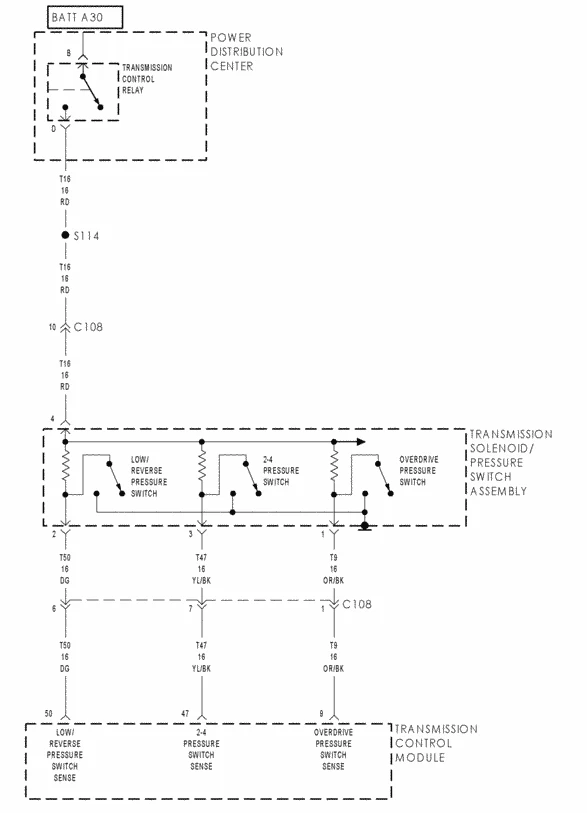

I also realized that, in my mind, I had been thinking of pressure sensors as a pull-down circuit with the high reference and resistor being internal to the ECU when in reality this circuit used a high reference shared with the solenoids and resistor internal of the pack. (Figure 4)

Figure 4

Therefore, when the solenoids are commanded on there is a current load on the voltage supply for the pressure switches. When the solenoids are on, in transition the current load is highest, amplifying the condition.

This indicated there must be a voltage drop (resistance) in the shared power supply to the solenoids and pressure sensors that are temperature sensitive. With the B+ circuit to the solenoid pack retested and no voltage drop found to the external connector when the condition occurred, I felt it had to be internal of the solenoid pack.

With a broader search for a solenoid pack nothing new was found but I did locate a rebuilt part and decided it was my best option. Once I received and installed the rebuilt solenoid pack I road tested the car several more times without any fault codes or drivability concerns.

I was relieved that this concern was resolved, but irritated it took three solenoid packs to get a good one. I still needed to look back at my diagnosis process to find how I can improve the process of pinpointing the concern. First, as I indicated above, I wasn't fully thinking of the pressure sense correctly, and next, due to lack of experience with the scope and using an inexpensive unproven pressure transducer, I wasn't fully trusting my analysis of the patterns.

In summary, I want to encourage the use of the technology available, develop your skills with it, and when that problem car shows up learn from the challenges and grow confidence daily. The job is never easy but can certainly be rewarding when we finally get it right.

Certified Transmission

Certified Transmission