Have you found yourself looking for an engine knock, squeak, or rattle that turned into something else? I found myself doing a lot more of that this year.

Today's topic applies to the 2016 through 2019 model year Ford Escape with either the 1.5L or 1.6L Ecoboost engines. I have had several this year with damaged and/or broken flexplates (seven of them in the last eight months), and four of these jobs had NO dowel pins in them! None of them looked like they had ever been apart, and two of them were the original owners of the vehicles that had stated that NO engine or transmission work had ever been performed. How can that be? Is it possible that they came this way from the factory? When doing some research, I did come across this bulletin:

SSM 48725 - 2016-2019 Escape - 1.5L EcoBoost/1.6L EcoBoost - Replacement Of The Flexplate

2016-2019 Escape vehicles equipped with the 1.6L EcoBoost or 1.5L EcoBoost engines may have missing or damaged dowel alignment pins between the engine and transaxle. When either a new long block or new short block is installed in the vehicle and the dowel pins were found missing or damaged upon disassembly of the original engine, the flexplate (6375) must be replaced. For engine overhauls or other engine related repairs where the engine and transaxle do not require separation, replacing the flexplate is not required. This direction also applies to existing service publication repairs where the engine and transaxle are separated as part of the repair procedure. Refer to Workshop Manual (WSM), Section 303-01.

A SSM from Ford is a "Special Service Message". To me this might seem a little more important than an SSM; maybe a TSB should have been issued? This seems like a potentially critical problem that warrants a TSB.

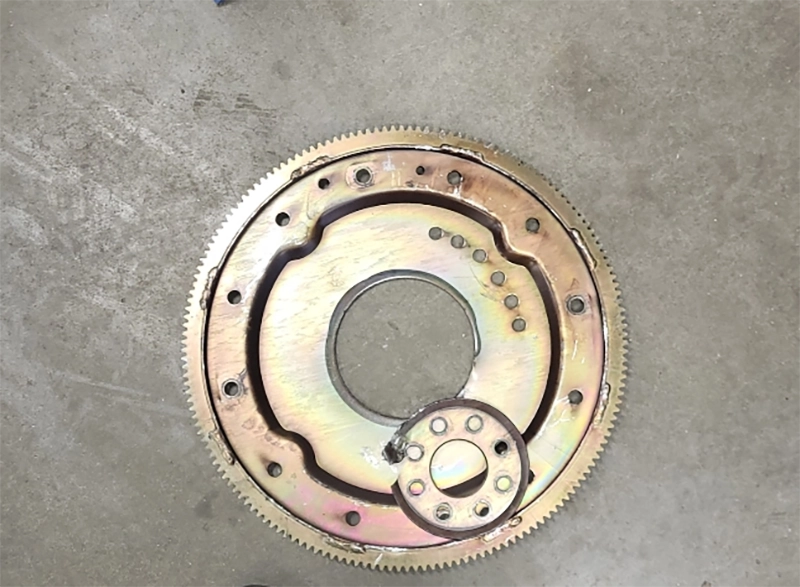

We see firsthand the issues that are created when we have engine/transmission alignment issues and the resulting damage that can occur. This is not limited to a single make or model as we know that flexplate damage can occur even if everything thing is in place and secure. The extent of the damage can vary greatly depending on how long the customer decides to keep driving the vehicle after they notice a noise. Here are a few other examples, the first one being a Ram 6.7L Diesel. (Figure 1)

Figure 1

This next example is pretty bad. The flexplate is destroyed and it also took out the motor plate (adapter between engine block and transmission), and the starter, too. The customer said there was no warning; the vehicle just stopped moving. The flexplate was replaced at a different shop that did not check for a reason it was broken, and there were no dowel pins installed after an engine replacement from what we see. For this application, we highly recommend that the flexplate be upgraded to a billet version whenever you are replacing the transmission, or if the transmission is pulled is to replace the flexplate. (Figure 2)

Figure 2

Not only was the flexplate in two pieces, but both the converter pilot and the crankshaft were damaged beyond repair, and the transmission pump was also taken out. I do not know how long they had it running after it was broken but this one caused a lot of damage. (Figure 3)

Figure 3

Whenever you have a transmission removed a careful inspection needs to be performed; this can save you both time and money by making sure everything is 100% when you are done with your repairs. Our company policy for our R&R technicians is to have them remove and inspect the flexplate on every vehicle we are installing a transmission on. This does two things for us: One, we can make sure there are no telltale signs of a flexplate that could possibly crack/break in the near future, and two, it also allows us to get a good look at the rear main seal.

Those of us in the transmission industry know how important it is to make sure that things are aligned correctly; this does not just apply to the topic at hand, but also applies to driveshafts, CV axles, and shift linkages. All these components need to be in good working order for the proper operation of the vehicle.

Certified Transmission

Certified Transmission