We all have routines. We live, eat, sleep, play and work by them. They help us get things done faster and more efficiently. Sometimes they are the fabric that holds us together, sometimes not so much. Anyone that's been around this profession for any amount of time probably knows that the next ticket in the queue has a good chance of being anything but a routine repair.

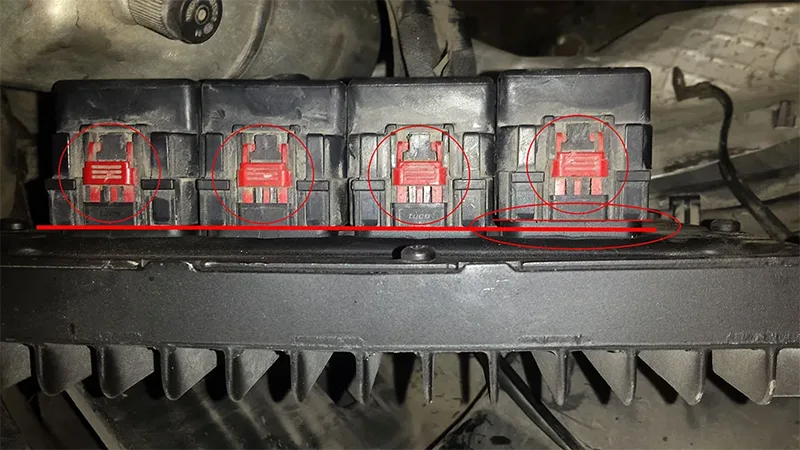

Such was the case with a 2005 Dodge Dakota that rolled in to our shop equipped with 4WD, 4.7L engine, and a 545RFE transmission. Trucks like these are our bread and butter being located on the border of a big city with lots of farming and commercial operations on the other side. The customer's complaint was "It feels like it's slipping once in a while." We have a routine for our initial evaluation like everyone else: check fluid levels, scan for codes, test drive, and perform an undercar inspection. While checking fluid levels I noticed this: A new/reman PCM (figure 1). Possibly not that it is relevant at this point, but something to make note of.

Figure 1

Another of our routines starts at the counter when the service advisor is getting information from the customer. We ask a specific question: have you had any other work done on your vehicle in the last year? You may or may not be surprised at the answers you will get. Our front office staff is pretty good about prying information out of the customer, but a lot of times the information that the customer provides is grossly inaccurate and that can make a difference between having an accurate concern identified on the repair order or what I like to call a, "search warrant". This customer had stated that he had not had any repairs done recently, so let's move on with our initial inspection.

Fluid levels are good and the transmission fluid looks pretty fresh. Almost too fresh for 178K on the clock, and there are multiple codes stored in several modules. O2 heater B1S1 sensor, no closed loop operation, SKIM key code not stored, and on the transmission side we have a P0869 line pressure high, P0988 4C pressure switch rationality, and P0888, transmission relay always off. There were also codes stored in the airbag and ABS modules for lost communication with the PCM.

Moving on with the road test, things seemed pretty normal. The transmission shifted ok until a few minutes in. I usually record a data capture while test driving, but before I knew it the vehicle went into limp mode and the scanner had lost communication. At that time I still had communication between all the other modules except for the PCM. Cycling the key seemed to restore normal operation, so I decided to clear all the codes and start from scratch. It didn't take long for the PCM to start acting up again. After a short test drive it went into limp mode and the P0888 (transmission relay always off) returned as a pending code. At that same time I also lost communication with the PCM on my scan tool and it also reset the lost communication codes for the CAN C bus in the ABS and airbag modules.

At this point I knew I needed some diagnostic time to figure out what was going on. After getting additional diagnostic time approved it was time to decide where I wanted to go with this. Did the loss of communication cause limp mode and the P0888, or did the egg come before the chicken?

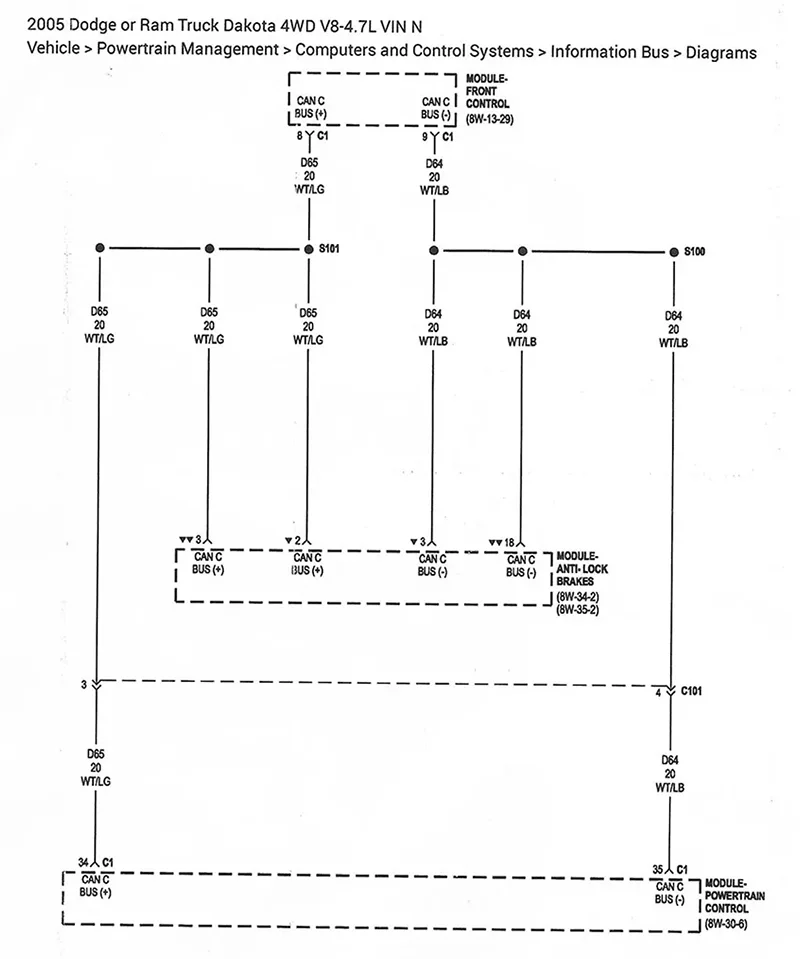

If the PCM has a problem with communication I'm going to verify the basics: powers, grounds, data lines, and then make a determination based on what I find. If I find some new parts installed on a vehicle I always start with the installation of the parts involved. I accessed the new PCM and lo and behold, what did I find? (figure 2).

Figure 2

See that connector on the right that is not fully seated? Notice that the connector locks for the other connectors aren't locked either. The loose connector on this configuration is C1; a pretty important connector on Chrysler systems. Guess what it supplies to the PCM? Data lines? Check. Most of the power and grounds? Check.

I seated the connector and heard that "click" that we all like to hear when we connect something and re-checked my work. No such luck, but I thought I'd get lucky and earn my hour or so of diagnostic time but now I have to get the brain cells out.

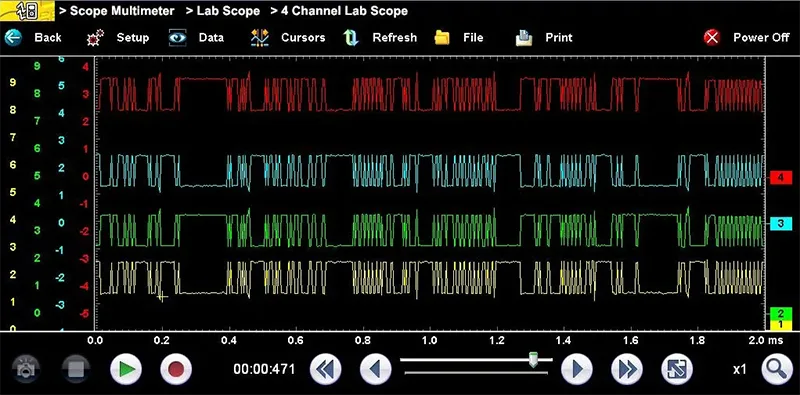

At this point I'm concerned about the functionality of the PCM. With the loss of communication resulting in limp mode, coupled with the loss of communication codes stored in the ABS and airbag modules tells me we needed to check the basic functions of the PCM. Looking at the schematic for the CAN C lines, the only modules on that circuit are the PCM, ABS, and airbag modules that communicate to the scanner via the TIPM. On a lot of vehicles, you can scope the CAN lines straight from the DLC pins 6 and 14, however on this common Chrysler setup pins 6 and 14 only communicate with the TIPM. The CAN signals from there are transmitted to the other modules on the CAN C network. (figure 3)

Figure 3

I decided that I needed to verify the CAN networks ability to transmit and receive messages as well as verifying the correct powers and grounds that will let the PCM function as designed. The easiest thing to do (I like easy) was to scope the CAN signals at a couple of modules to verify there is a signal present. I hooked up my lab scope to the CAN+ and CAN at the PCM and ABS modules to compare signals (figure 4).

Figure 4

We can see that the CAN HI signal is being pulled from 3.5v to 2.5v, CAN LOW is pulled up from 1.5v to 2.5v. The top capture was taken at the PCM; the bottom capture was taken at the ABS module. The signals indicate that the CAN network is intact, and there are no discrepancies in the waveform. From there, I verified correct voltage supply to the PCM, and all grounds voltage dropped at less than 5mv, which is actually pretty good for a 13 yr old vehicle. These readings were all taken while the condition was occurring, leading me to believe that this PCM had internal issues.

A remanufactured PCM was ordered from a fairly reputable supplier that we've used in the past. After installing the new PCM, the engine had a definite misfire and set a P2313 - insufficient coil burn time on cylinder #8. Yep, the new PCM had a bad coil driver for that cylinder. It ran fine with the original PCM, so we got another one on the way. I'm very hesitant to install used or reman PCMs (especially on Chrysler products) because I've seen way too many issues that have resulted in a new problem after the PCM is replaced.

After replacing the PCM once again, the engine ran like a champ, the transmission shifted great, and test drove a few times for about an hour total and no transmission codes had set. The O2 sensor code returned, but the customer is kind of a DIY guy and said he would take care of it himself.

Fortunately, this diagnosis was fairly easy. Being able to reproduce the issue along with an understanding of how the system works and a logical diagnostic path to follow helped a lot, not to mention that the components in question were easily accessible. This one is out the door and now it is time to move on to the next routine diagnosis.

Certified Transmission

Certified Transmission